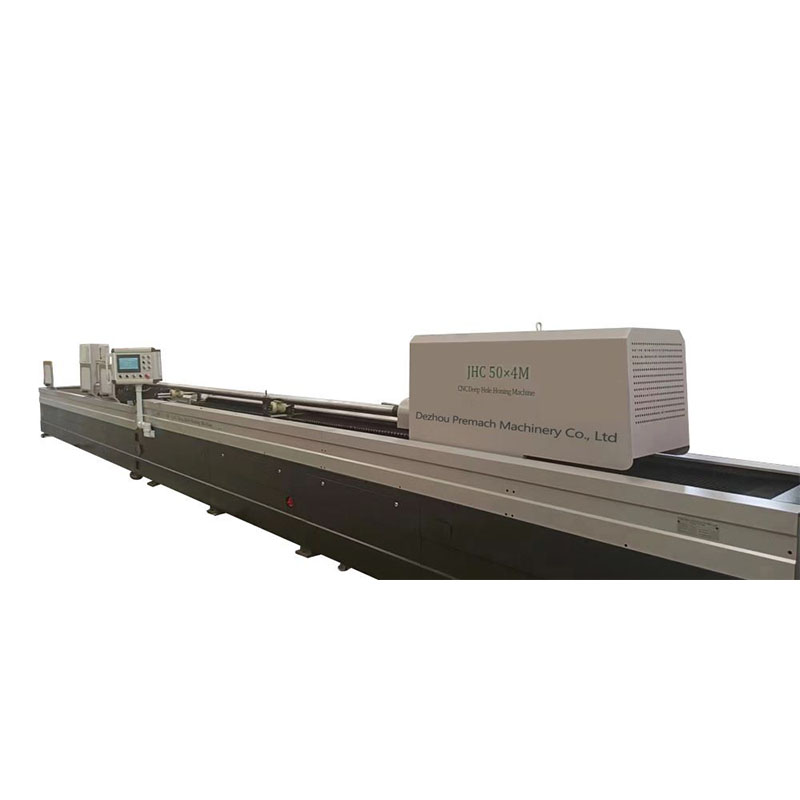

Factory Directly Small Engine Boring Bar - Hones, CNC Deep Hole Honing Machine 2mk2125/2mk2135/2mk2150 Series With Iron Casting Bed – Premach

Factory Directly Small Engine Boring Bar - Hones, CNC Deep Hole Honing Machine 2mk2125/2mk2135/2mk2150 Series With Iron Casting Bed – Premach Detail:

Video Display

Function Description

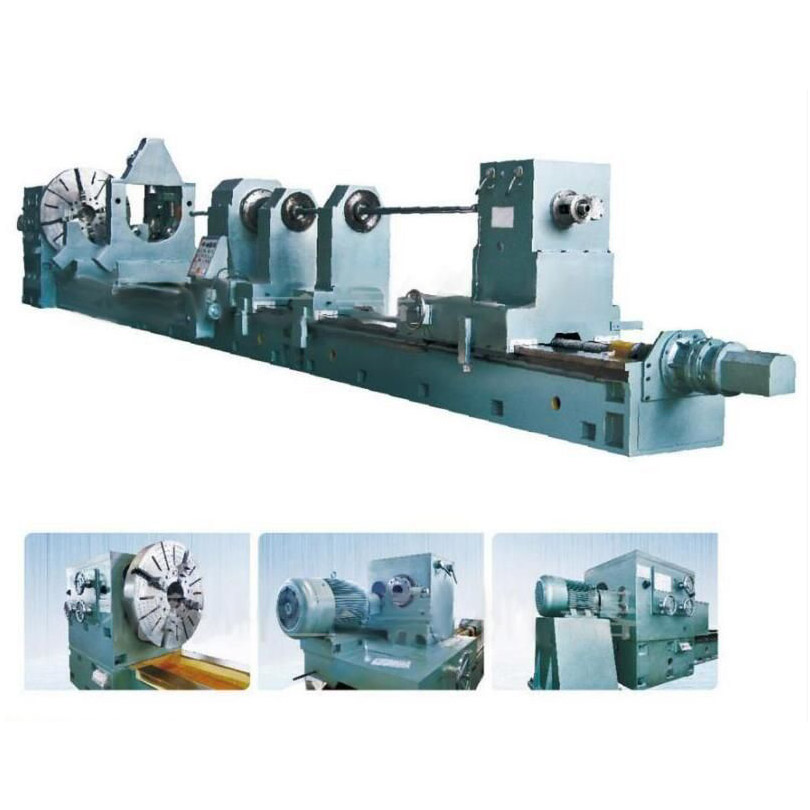

This machine is mated with CNC system, AC servo moto, travel head with rotating honing rod adopts stepless speed. It is mated with high accuracy racks and gears to realize the reciprocating of honing head and it can control the honing position too. Mated with double linear guide way, so it has long life and high accuracy. The honing head adopt hydraulic constant pressure expanding. Sand blades always maintain constant pressure to be sure the roundness and cylindricity of the workpiece. Honing pressure can be adjusted according to requirement and its device for high- and low-pressure control can realize the rough and finish honing on the operate station. The machine’s other equipment such as hydraulic valve, automatic lubrication station is using the well-known brand products.

Of course, the CNC system, linear guide way and hydraulic valve can also be chosen by customer.

Technical parameter

|

Name |

Item |

Parameter |

||

|

2MK2125 |

2MK2135 |

2MK2150 |

||

|

Working capacity |

Honing Dia. |

Φ30-250mm |

Φ60-350mm |

Φ60-500mm |

|

Honing depth |

1000-12000mm |

|||

|

Clamped Dia. range of workpiece |

Ф50mm-Ф300mm |

Ф75mm-Ф400mm |

Ф150mm-Ф1400mm |

|

|

Spindle of travel head with rotating honing rod |

Center height |

350mm |

350mm |

1000mm |

|

Spindle speed |

25-250rpm, 2 gears, stepless |

|||

|

Reciprocating travel speed |

4-18000m/min, stepless |

|||

|

Motor And cooling system |

Motor power of travel head with rotating honing rod |

11 KW(frequency converting motor) |

15 KW(frequency converting motor) |

|

|

Feed motor power |

5.5KW, servo motor |

11KW, servo motor |

||

|

Flow of cooling pump |

100L/Min. |

|||

|

Work pressure of hydraulic pump station for expanding honing head |

4 MPa |

|||

|

Machining accuracy |

Machining accuracy |

IT7-IT8 |

IT7-IT8 |

IT7-IT8 |

|

Machining roughness |

Ra0.4μm-Ra0.2μm |

Ra0.4μm-Ra0.2μm |

Ra0.4μm-Ra0.2μm |

|

|

CNC system |

KND, SIEMENS 802, FANUC or others, optional by customer. | |||

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction for Factory Directly Small Engine Boring Bar - Hones, CNC Deep Hole Honing Machine 2mk2125/2mk2135/2mk2150 Series With Iron Casting Bed – Premach , The product will supply to all over the world, such as: New York, Somalia, Malaysia, With many years good service and development, we have a qualified international trade sales team. Our goods have exported to North America, Europe, Japan, Korea, Australia, New Zealand, Russia and other countries. Looking forward to build up a good and long term cooperation with you in coming future!

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!