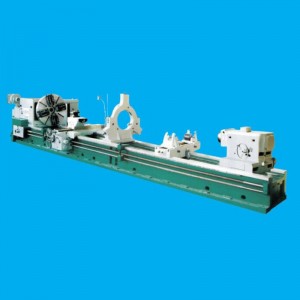

Horizontal Engine Lathe

-

horizontal engine conventional lathe CW6163E,CW6180E,CW61100E,CE61200E

The lathe bed is of an integral floor type structure. It is integrally cast. After casting and rough machining, it is subject to aging treatment to ensure the structural rigidity of the whole machine. The guide way surface is subject to medium frequency quenching, the hardness is not less than HRC52, the hardening depth is not less than 3mm, and the stability of the whole machine is good.

The reasonable structure design ensures that the lathe has sufficient static and dynamic rigidity. The advanced technology ensures that the machine has good quality, low noise and small vibration.

Beautiful appearance, combined with ergonomic principles, easy adjustment of workpieces, easy operation and maintenance.

The main parts such as the bed, headstock, carriage and tailstock are made of high-quality resin sand castings. After natural aging and artificial aging, the main parts of the machine are guaranteed to have low deformation and high stability.

The spindle adopts a three support structure, with reasonable span, low noise, low heat generation and good accuracy retention.

The spindle has a wide speed range, stable operation, low temperature rise and good accuracy retention.

The main transmission gear is hardened and ground to ensure its high accuracy, smooth operation and low noise.

High cutting power and high processing efficiency.

-

horizontal engine lathe CWA61100-CWA61160

This machine tool is a universal conventional lathe, which is suitable for turning outer circle, end face, grooving, cutting, boring, turning inner cone hole, turning thread and other processes of shaft parts, cylindrical and plate parts of different materials with high-speed steel and hard alloy steel tools. The spindle adopts a three-support structure, and the bed adopts an integral bed, so that the bed has high rigidity, and the apron, tool post, and saddle can move quickly. This machine tool has the advantage of strong rigidity, high efficiency, Safe and reliable, easy to operate and beautiful in appearance.

-

horizontal engine conventional lathe CW6163,CW6180(A),CW61100(A),CE61200(A)

This machine tool is a universal engine concentional lathe, which is suitable for turning outer circle, end face, grooving, cutting, boring, turning inner cone hole, turning thread and other processes of shaft parts, cylindrical and plate parts of different materials with high-speed steel and hard alloy steel tools. The spindle adopts a three-support structure, and the bed adopts an integral bed, so that the bed has high rigidity, and the apron, tool post, and saddle can move quickly. This machine tool has the advantage of strong rigidity, high efficiency, Safe and reliable, easy to operate and beautiful in appearance.

-

horizontal engine conventional lathe CW61128-CW611208

This series of engine conventional lathes can undertake various turning tasks. It can turn the outer circle, inner hole, end face, metric thread, inch thread, modulus and pitch thread and other shaped surfaces of various parts. The upper slide can be used to turn short tapers independently. The upper slide can also be used to machine long tapers when it is matched with the longitudinal feed of carriage. It can also meet the process requirements of drilling, boring and trepanning. It is also suitable for powerful turning with carbide tools, Processing of various ferrous and non-ferrous metals.

-

horizontal engine conventional lathe CW61126-CW611206

This series of engine conventional lathes has been continuously updated and improved by our company for more than 40 years, after absorption of advanced design and manufacturing technologies at home and abroad, and after use of users in aerospace, railway, valve and other industries, the practice has proved that the large horizontal lathes produced by our company have reached the advanced level in China.

The technical features of this series of lathes are as follows: first, the basic parts, the spindle tailstock quill, etc. have passed the optimization design and fine processing, with high precision and life; second, the key components, such as the spindle bearings and the main electrical components, are all famous brands at home and abroad.

-

engine lathe, conventional lathe C6236

This series of high-speed engine lathe can perform various turning tasks, such as turning internal and external cylindrical surfaces, conical surfaces, end faces and various threads – metric and inch threads, as well as drilling, reaming and oil drawing grooves. This machine tool can process steel, cast iron and non-ferrous metals. The dimensional accuracy of the parts processed by this lathe can reach IT6-IT7, and less roughness can be obtained. In addition to the above turning work, the saddle lathe is especially suitable for the processing of disc parts and odd shaped parts.

-

horizontal engine lathe C6251-C6251V

A

Novel appearance

The appearance design of the lathe integrates the ergonomics concept into the mature machine tool structure to enhance the operating feel. The striking red and gray stamping parts are used for the main sheet metal parts, and the overall effect is beautiful.

B

Neat specifications

CA series products have complete specifications and various categories. Including straight bed lathe, saddle bed lathe and large diameter lathe.

C

Complete functions

CA series lathes can be used for turning end faces, internal and external cylinders, conical surfaces and other rotating surfaces of various materials. More accurate processing of various metric, inch, module, diametral pitch threads. In addition, drilling, reaming, pulling oil grooves and other work can also be easily competent.

D

Excellent performance

The 40A series ordinary lathe is equipped with a large diameter spindle front bearing, and has a wider bed span compared with similar products, achieving higher structural rigidity, so that the product performance reaches a new height.

standard accessories: Three jaw chuck Variable diameter sleeve and centers Oil gun Tool box and tools 1 set.