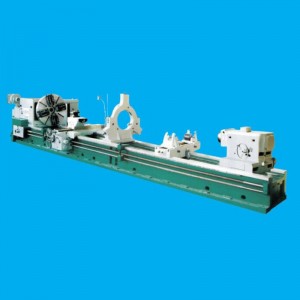

horizontal engine conventional lathe CW6163E,CW6180E,CW61100E,CE61200E

Use and characteristics

This machine tool is a universal general-purpose lathe, which is suitable for turning outer circle, end face, grooving, cutting, boring, turning inner cone hole, turning thread and other processes of shaft parts, cylindrical and plate parts of different materials with high-speed steel and hard alloy steel tools. The machine body has high rigidity, and the apron, tool post and saddle can move quickly. This lathe has the characteristics of strong rigidity, high efficiency, safety and reliability, easy operation and beautiful appearance.

main parameters

|

Model |

|||||||||

| specification |

CW6163E CW6263E |

CW6180E CW6280E |

CW61100E CW62100E |

CW61120E CW62120E |

|||||

|

capacity |

|||||||||

| Swing diameter over bed | 630mm (25") | 800mm (32”) | 1000mm (39.4") | 1200mm (47.2”) | |||||

| Swing diameter over cross slide | 350mm (13.8") | 485mm (19”) | 685mm (27") | 800mm (31.5”) | |||||

| Swing diameter over gap | 830mm(32.7",CW6263E) | 1000mm(39.4",CW6280E) | 1200mm(47.2",CW62100E) | 1400mm(55",CW62120E) | |||||

| Distance between centers |

750mm, 1250mm, 1750mm, 2750mm, 3750mm |

||||||||

| Valid length of gap |

230mm (8") |

||||||||

| Width of bed |

550mmmm (21.7”) |

||||||||

|

headstock |

|||||||||

| Spindle nose |

D11 or C11 |

||||||||

| Spindle bore |

105mm (4.1") or 130mm (5.1”, optional for CW6180E-CW61200E) |

||||||||

| Taper of spindle bore |

1:12, Φ120mm (Φ140mm optional for CW6180E-CW61200E) |

||||||||

| Range of spindle speed (Number) |

18 changes 14-750r/min |

||||||||

|

Gear box-threads and Feed |

|||||||||

| Rapid travel: longitudinal/cross |

4000mm/2000mm/min |

||||||||

| Lead screw size:Diameter/pitch |

T48mm/12mm or T55mm/12mm (above 5000mm length lathe) |

||||||||

| Longitudinal feeds range |

72 kinds 0.048-24.3mm/rev (0.0019"-09567"/rev) |

||||||||

| Cross feeds range | 72 kinds 0.024-12.15mm/rev (0.00098"-0.4783"/rev) | ||||||||

| Metric thread range |

54 kinds 1-240mm |

||||||||

| Inch thread range |

36 kinds 28-1 inch |

||||||||

| Diameter thread range | 27 kinds 30-1T.P.I. | ||||||||

| Modular thread range |

27 kinds 0.5-60D.P. |

||||||||

|

carriage |

|||||||||

| Cross slide travel |

350mm |

420mm |

520mm |

620mm |

|||||

| Compound rest travel |

200mm |

||||||||

| Size of tool shank |

32x32mm |

||||||||

|

Tailstock |

|||||||||

| Quill diameter |

100mm (3.94”) |

||||||||

| Quill travel |

240mm (9.45”) |

||||||||

| Quill taper |

MT No.6 |

||||||||

|

Motor |

|||||||||

| Main motor power |

7.5kW(15HP)3PH |

||||||||

| Coolant pump power |

0.09KW, 3PH |

||||||||

| Rapid travel motor power |

1.1KW |

||||||||

|

Dimension and weight |

|||||||||

| Overall dimension (LxWxH) |

|

||||||||

| Center distance (1500mm) | 3452x1326x1390mm CW6180E | ||||||||

| Net weight |

4300KG |

4500KG |

5000KG |

5500KG |

|||||