Featured Products

-

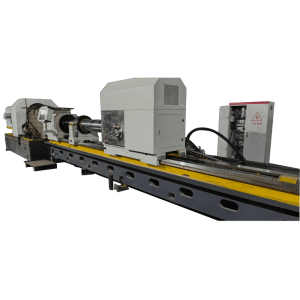

China Gold Supplier for (CNC) Large Spindle Bore Oil Country Pipe Threading Lathe CW6646

This machine tool is designed and manufactured for thread processing of oil pipe, drill pipe and casing in petroleum, chemical and metallurgical industries. It can turn all kinds of internal and external threads (metric, inch and taper pipe threads) accurately through the automatic control of CNC system. It is especially suitable for thread processing with mass production. This machine can also process rotary parts. For example, rough and finish machining of internal and external cylindrical surfaces, conical surfaces, circular surfaces, and medium and small batches of shaft and disk parts. It has the characteristics of high automation, simple programming and high machining accuracy.

The machine tool has two linkage control axes, semi closed loop control. The Z-axis and X-axis use ball screw pairs and AC servo motors to achieve vertical and horizontal movement, with good positioning accuracy and repeated positioning accuracy.

-

Quots for Insert Type Deep Hole Gundrilling Tool

Bear “Customer initially, High-quality first” in mind, we work closely with our prospects and supply them with efficient and specialist companies for Quots for Insert Type Deep Hole Gundrilling Tool, With a wide range, top quality, acceptable charges and great assistance, we are going to be your finest business partner. We welcome new and previous prospects from all walks of lifetime to get in touch with us for upcoming small business interactions and accomplishing mutual achievem... -

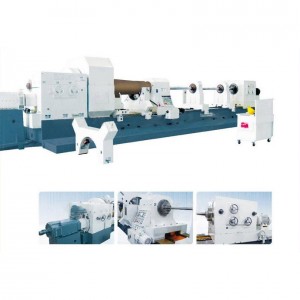

Professional China Ck1335 Ck350 Big Spindle Bore Horizontal Metal Turning Oil Machine Pipe Threading Machine CNC Pipe Lathe CNC Machine Metal Pipe Thread CNC Lathe

*Big spindle bore and double chuck to ensure process big diameter pipe. *One-piece bed adopts high strength iron to ensure rigidity and precision. *Ultrasonic frequecncy quenched guide ways ensure good wear-resistance. *Carriage and guide way contact surface use Turcite B to maintain accuracy.

-

2019 Latest Design Gun Drill with CE Certificate CNC Deep Hole Boring Machine (ZJZ500)

This machine is a deep hole processing equipment for drilling cylindrical bar materials. It is a high-efficiency, high-precision and high-automatic machine tool for drilling small holes with external chip removal method (gun drilling method). Through one continuous drilling, the processing quality that can be guaranteed by the general drilling, expanding and reaming procedures can be achieved. The hole diameter accuracy is IT7-IT10, the surface roughness is Ra3.2-0.04μm, and the straightness of the hole center line is ≤0.05mm/100mm.

-

Europe style for Customized High-Accuracy Horizontal Deep Hole Solid Drilling and Hollow Boring Machine

T2180 is a big cylinder drilling and boring machine, which can perform the processing function of drilling, boring and trepanning the large workpiece with big diameter. While working, the workpiece rotates slowly and the cutting tool rotates in high speed and feed. BTA chip removal method is used for drilling and forward metal chips removal inside boring rod by cutting liquid for boring.

-

Factory Cheap Hot 4 Spindles Mlt Nc System Gun Drilling Machine for Feed Mold Ring-Die Livestock and Biomass Mill

This machine is a deep hole processing equipment for drilling cylindrical bar materials. It is a high-efficiency, high-precision and high-automatic machine tool for drilling small holes with external chip removal method (gun drilling method). Through one continuous drilling, the processing quality that can be guaranteed by the general drilling, expanding and reaming procedures can be achieved. The hole diameter accuracy is IT7-IT10, the surface roughness is Ra3.2-0.04μm, and the straightness of the hole center line is ≤0.05mm/100mm.

-

Best Price on Rotary Ultrasonic Welding Machining Tool Ultrasonic Assisted Drilling

2MK2125, 2MK2135 and 2MK2150 series CNC deep hole honing machine adopt iron casting bed, is suitable for honing and burnishing cylindrical deep-hole parts, such as various hydraulic cylinders. It can also perform honing and burnishing step holes, and the hole diameter accuracy after honing can reach IT8-IT9, the surface roughness can reach Ra0.2-Ra0.4μm. it can also repair the taper, ellipticity and partial hole tolerance with the partial honing. It can directly perform high efficiency honing of cold drawing steel pipes. This series deep hole honing machine is an ideal machine for deep-hole machining with high accuracy and high efficiency.

-

2019 New Style 4u Drill Wcgt080412-Ak CNC Cutting Tool Deep Hole Drilling Tool Insert

T2150 deep hole drilling and boring machine is the heavy machine tool. The workpiece is positioned by a taper plate while boring, and that is clamped by a three-jaw chuck during drilling. The oil pressure head adopts the spindle structure, which greatly improves the bearing performance and the rotation accuracy. The guide way adopts a high rigid structure suitable for deep hole machining, with large bearing capacity and good guiding accuracy; The guide way is quenched and has high wear resistance. The machine tool has the functions of drilling, boring, rolling and trepanning. Suitable for machining the center hole of shaft parts. PLC control system and touch screen are adopted for simple operation; The above ground oil tank is adopted for the cooling system.

-

Hot New Products CNC Deep Hole Drilling Do a Professional Deep Hole Processing Machine, Do Not Meet on The Limitations of Gun Drilling Processing Forage Vrtani Poraus

This machine is a deep hole processing equipment for drilling cylindrical bar materials. It is a high-efficiency, high-precision and high-automatic machine tool for drilling small holes with external chip removal method (gun drilling method). Through one continuous drilling, the processing quality that can be guaranteed by the general drilling, expanding and reaming procedures can be achieved. The hole diameter accuracy is IT7-IT10, the surface roughness is Ra3.2-0.04μm, and the straightness of the hole center line is ≤0.05mm/100mm.

-

Super Lowest Price Ztk CNC Heavy Duty Deep-Hole Drilling and Boring Machine/Customerized Machine

T2150 deep hole drilling and boring machine is the heavy machine tool. The workpiece is positioned by a taper plate while boring, and that is clamped by a three-jaw chuck during drilling. The oil pressure head adopts the spindle structure, which greatly improves the bearing performance and the rotation accuracy. The guide way adopts a high rigid structure suitable for deep hole machining, with large bearing capacity and good guiding accuracy; The guide way is quenched and has high wear resistance. The machine tool has the functions of drilling, boring, rolling and trepanning. Suitable for machining the center hole of shaft parts. PLC control system and touch screen are adopted for simple operation; The above ground oil tank is adopted for the cooling system.

-

Renewable Design for 10″ Large Spindle Bore CNC Pipe Threading Lathe (CNC Oil Country Lathe)

This machine tool is designed and manufactured for thread processing of oil pipe, drill pipe and casing in petroleum, chemical and metallurgical industries. It can turn all kinds of internal and external threads (metric, inch and taper pipe threads) accurately through the automatic control of CNC system. It is especially suitable for thread processing with mass production. This machine can also process rotary parts. For example, rough and finish machining of internal and external cylindrical surfaces, conical surfaces, circular surfaces, and medium and small batches of shaft and disk parts. It has the characteristics of high automation, simple programming and high machining accuracy.

The machine tool has two linkage control axes, semi closed loop control. The Z-axis and X-axis use ball screw pairs and AC servo motors to achieve vertical and horizontal movement, with good positioning accuracy and repeated positioning accuracy.

-

Fast delivery China Manufacturer CNC Drilling Machine CNC Deep Hole Gun Drilling Machine for Automobile Light Mould

This machine is a deep hole processing equipment for drilling cylindrical bar materials. It is a high-efficiency, high-precision and high-automatic machine tool for drilling small holes with external chip removal method (gun drilling method). Through one continuous drilling, the processing quality that can be guaranteed by the general drilling, expanding and reaming procedures can be achieved. The hole diameter accuracy is IT7-IT10, the surface roughness is Ra3.2-0.04μm, and the straightness of the hole center line is ≤0.05mm/100mm.