Featured Products

-

Factory supplied European Standard Europ Design CNC Slant Bed Turning Lathe

CNC end face turning lathe, through the automatic control of CNC system (FANUC/SIEMENS/GSK/KND, etc), can be used for turning various kinds of inner hole, outer circle, conical surface, circular arc surface and thread.

-

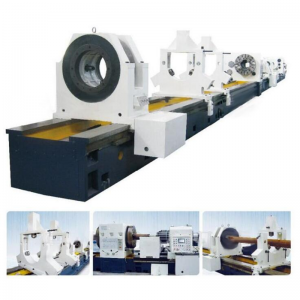

ODM Supplier Hollow Spindle Oil Country Lathe Machine (Pipe Threading lathe Q1327)

This series of machine tools are mainly used for pipe thread processing, and can cut metric and inch cylindrical and conical pipe threads. It is suitable for processing tubing, casing, drill pipe, etc. in petroleum, metallurgy, chemical, hydropower, geology and other departments.

Mated with CNC system, with high control precision and good reliability. The machine tool can also adopt PLC controller, which improves the reliability and control flexibility of the machine tool.

-

Supply OEM/ODM C6241/2000 China Engine Lathe Machine

This series of high-speed engine lathe can perform various turning tasks, such as turning internal and external cylindrical surfaces, conical surfaces, end faces and various threads – metric and inch threads, as well as drilling, reaming and oil drawing grooves. This machine tool can process steel, cast iron and non-ferrous metals. The dimensional accuracy of the parts processed by this lathe can reach IT6-IT7, and less roughness can be obtained. In addition to the above turning work, the saddle lathe is especially suitable for the processing of disc parts and odd shaped parts.

-

Big Discount Cylinder Boring and Honing Machine Tool TM807A

This deep hole powerful honing machine is equipped with PLC controller or CNC system (optional), linear rolling guide way, AC servo motor, grinding rod adopts stepless speed regulation, stable commutation, convenient speed regulation, easy to ensure the accuracy of hole size, and reduce labor intensity. In the honing process, the sand rod and the workpiece always maintain constant pressure, so that the sand rod can be strongly ground. It ensures the high efficiency of deep hole machining, and is suitable for rough and fine honing of general cylindrical deep hole parts. This type of machine tool can also be used for partial honing to correct the taper and ellipticity of parts and the partial hole error.

-

China Factory for (CSD300) 300m Depth Borehole Drill Rig Hydraulic Rotary DTH Water Well Drilling Truck Mounted Oil Drilling Equipment Machine

ZSK2110B CNC deep-hole drilling machine adopt BTA chip removal to drill small diameter deep-hole workpieces, is very suitable for petroleum drill collar workpiece. The biggest characteristic of this machine is that: the front end of workpiece which near to the oil pressure head is clamped by double chucks and the rear end is clamped by annular steady rest.

-

100% Original Manual Engine Lathe Machine for Metal Turning 6 Feet Price List

This machine tool is a universal engine concentional lathe, which is suitable for turning outer circle, end face, grooving, cutting, boring, turning inner cone hole, turning thread and other processes of shaft parts, cylindrical and plate parts of different materials with high-speed steel and hard alloy steel tools. The spindle adopts a three-support structure, and the bed adopts an integral bed, so that the bed has high rigidity, and the apron, tool post, and saddle can move quickly. This machine tool has the advantage of strong rigidity, high efficiency, Safe and reliable, easy to operate and beautiful in appearance.

-

Factory Cheap Hot Tl-1600 CNC Deep Hole Drilling and Boring Machines for Mold Processing

ZSK2110B CNC deep-hole drilling machine adopt BTA chip removal to drill small diameter deep-hole workpieces, is very suitable for petroleum drill collar workpiece. The biggest characteristic of this machine is that: the front end of workpiece which near to the oil pressure head is clamped by double chucks and the rear end is clamped by annular steady rest.

-

2019 High quality Optimum 2 Meter Vheavy Duty Engine Lathe Machine for Hobby Use

This series of high-speed engine lathe can perform various turning tasks, such as turning internal and external cylindrical surfaces, conical surfaces, end faces and various threads – metric and inch threads, as well as drilling, reaming and oil drawing grooves. This machine tool can process steel, cast iron and non-ferrous metals. The dimensional accuracy of the parts processed by this lathe can reach IT6-IT7, and less roughness can be obtained. In addition to the above turning work, the saddle lathe is especially suitable for the processing of disc parts and odd shaped parts.

-

Europe style for 5 Axis Metal Processing Vertical CNC Machine for Aluminum Auto Part Steel Profiles Milling Drilling Tapping Price

T2150 deep hole drilling and boring machine is the heavy machine tool. The workpiece is positioned by a taper plate while boring, and that is clamped by a three-jaw chuck during drilling. The oil pressure head adopts the spindle structure, which greatly improves the bearing performance and the rotation accuracy. The guide way adopts a high rigid structure suitable for deep hole machining, with large bearing capacity and good guiding accuracy; The guide way is quenched and has high wear resistance. The machine tool has the functions of drilling, boring, rolling and trepanning. Suitable for machining the center hole of shaft parts. PLC control system and touch screen are adopted for simple operation; The above ground oil tank is adopted for the cooling system.

-

High Quality CNC Machine Hardened Guideway Siemens Fanuc CNC Lathe (Ck6140)

CNC end face turning lathe, through the automatic control of CNC system (FANUC/SIEMENS/GSK/KND, etc), can be used for turning various kinds of inner hole, outer circle, conical surface, circular arc surface and thread.

-

High Performance High Efficiency Conventional Bench Lathe From China Mainland Cw6180b

*brake equipment can make spindle stop very quickly, but motor don’t stop for better protection

*Supersonic frequency hardened bed ways;

*Precision roller bearings for spindle;

*High quality steel,ground and hardened gears inside headstock;

* Easy and fast operating gearbox;

*Enough strong power motor;

*ASA D4 camlock spindle nose;

*Various threads cutting functions available -

Low MOQ for Precision Honing Machine for Small Holes

2MK2125, 2MK2135 and 2MK2150 series CNC deep hole honing machine adopt iron casting bed, is suitable for honing and burnishing cylindrical deep-hole parts, such as various hydraulic cylinders. It can also perform honing and burnishing step holes, and the hole diameter accuracy after honing can reach IT8-IT9, the surface roughness can reach Ra0.2-Ra0.4μm. it can also repair the taper, ellipticity and partial hole tolerance with the partial honing. It can directly perform high efficiency honing of cold drawing steel pipes. This series deep hole honing machine is an ideal machine for deep-hole machining with high accuracy and high efficiency.