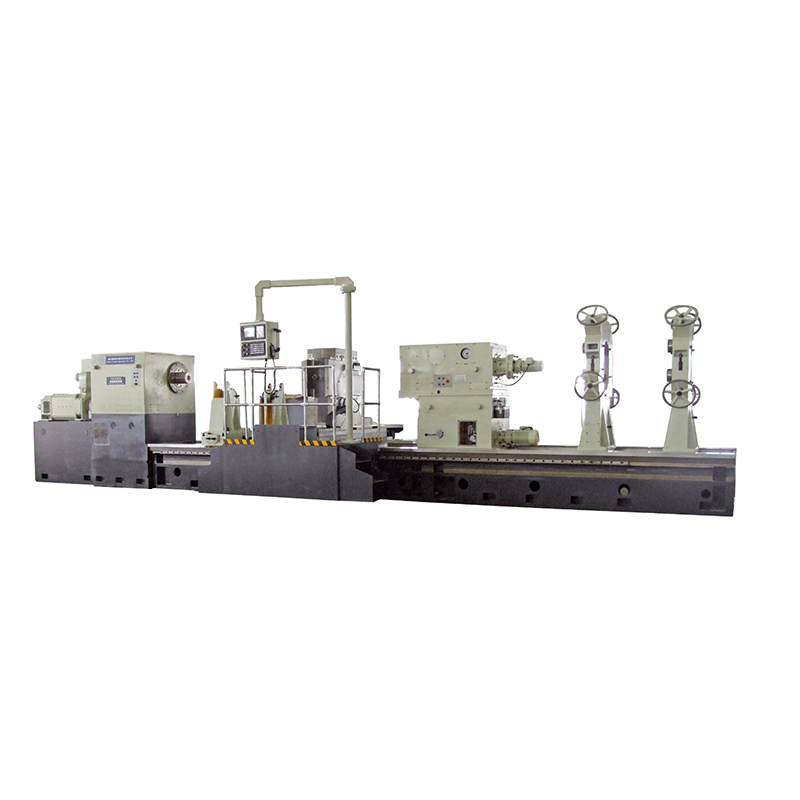

OEM Manufacturer Cnc Facing Lathe - Three guide ways heavy duty horizontal CNC lathe C61200S series – Premach

OEM Manufacturer Cnc Facing Lathe - Three guide ways heavy duty horizontal CNC lathe C61200S series – Premach Detail:

Product characteristic

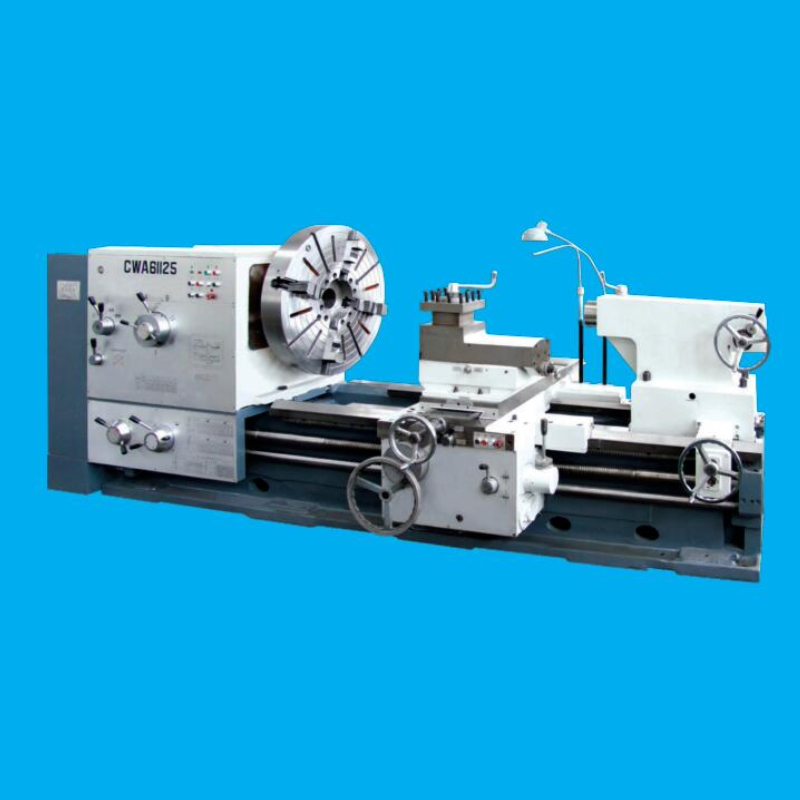

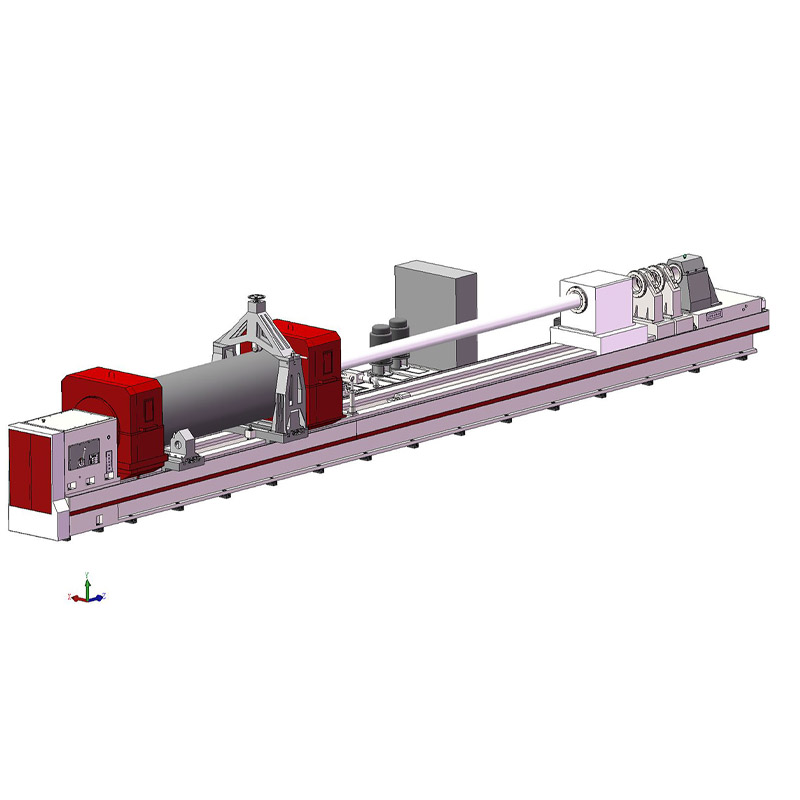

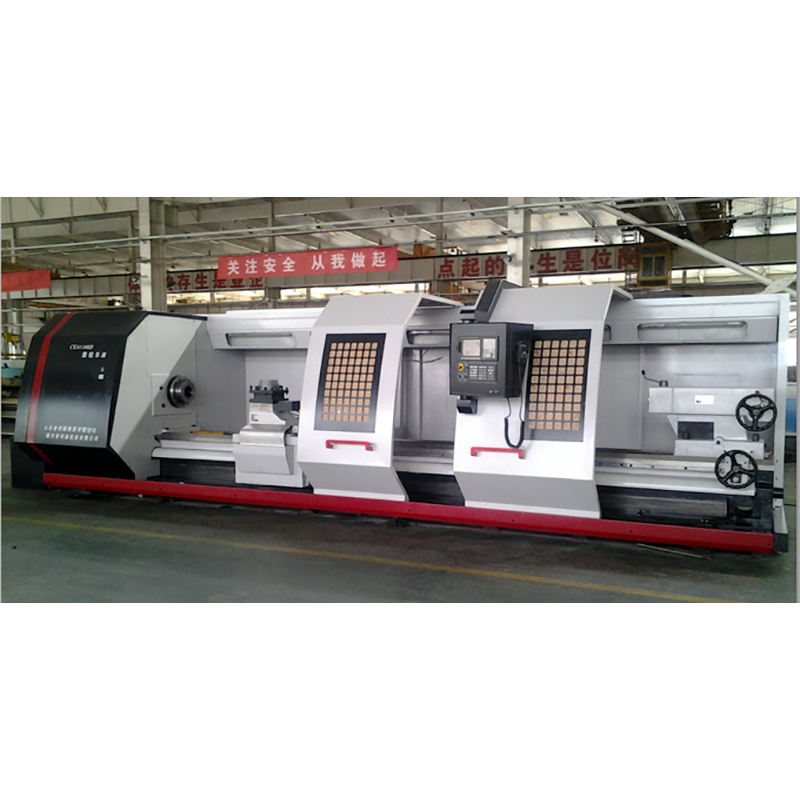

The C61xxS series is an improved series of heavy-duty horizontal lathes developed by our company based on our long-term experience in producing horizontal lathes and adopting internationally advanced design means and manufacturing technology. It is a well-designed product integrating electrical, automatic control, hydraulic control, modern mechanical design and other disciplines Mechatronic machine tool products integrating multiple categories of precision manufacturing technology. The structure and performance of the machine tool are applicable. The machine tool has the characteristics of high dynamic and static stiffness, long service life, high processing efficiency, safe and reliable functions, convenient operation and beautiful appearance.

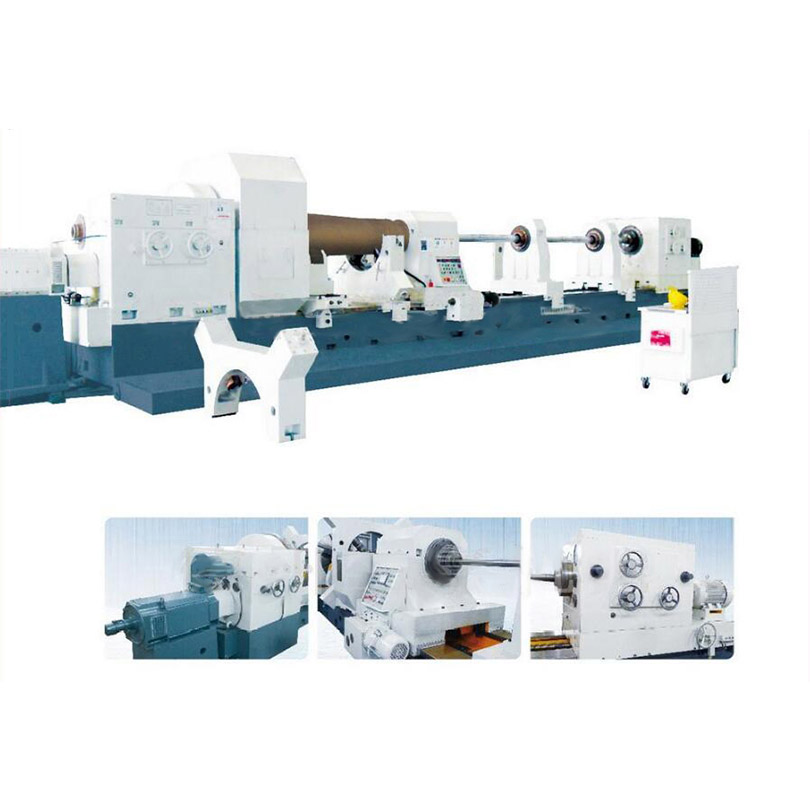

1. It is suitable for cutting tools such as high-speed steel and cemented carbide steel, turning outer circle, end face, grooving, cutting and boring shaft, cylinder and disc parts of ferrous metal, non-ferrous metal and some non-metallic materials.

2. The main drive and feed drive are of separate structure. The machine tool is a heavy-duty horizontal lathe with numerical control function.

3. The bed adopts integral three guide ways, and the guide way of the carriage bed adopt medium frequency quenching treatment.

4. The main drive is driven by the servo motor of the spindle, and the reasonable speed range of the spindle is realized through the mechanical two speed change.

5. The headstock box is of double-layer wall through shaft structure, and adopts double row short cylindrical roller bearing with high-precision adjustable radial clearance. Through optimization design, large spindle straightness and optimal bearing span are adopted to improve the rotation accuracy and dynamic and static stiffness. The center on the spindle adopts the flange type short taper handle structure, which improves the connection rigidity between the center and the spindle.

6. The tool post adopts the vertical tool plate structure, which can be used for strong cutting. The horizontal direction adopts ball screw, and the longitudinal direction adopts high-precision rack and double tooth bar clearance elimination structure. The large tool post is connected with the horizontal shaft of the feed box, which improves the transmission accuracy of the tool post.

7. The tailstock is an integral box structure. The core shaft in the sleeve is a double row short cylindrical roller bearing with high accuracy and adjustable radial clearance. The center is a flange type short taper shank center, which makes the tailstock have high rigidity. The sleeve and tailstock move in a mobile manner, and can be clamped and loosened automatically when in place. And is equipped with a hydraulic force measuring device.

8. The numerical control system adopts SIEMENS system, and other numerical control systems or digital display devices can also be selected by the user.

9. According to user requirements, we can provide double tool posts, milling and boring devices, grinding devices, etc.

MAIN TECHNICAL

|

specification |

Model |

||

|

C61200S |

C61250S |

C61315S |

|

| Max. swing diameter over bed | 2000mm | 2500mm | 3150mm |

| Max. swing diameter over carriage | 1600mm | 2000mm | 2500mm |

| Workpiece length | 6-25mm | ||

| Max. loading weight between centers | 63t | ||

| Diameter of face plate | 1600mm | 2000mm | 2500mm |

| Bed width | 2150mm | ||

| Front taper of spindle hole | Short taper flange type, taper 1:4 | ||

| Spindle speed range, mechanical two gears, stepless between gears | 0.63-125r/Mm hydraulic two gears, stepless | 0.5-100r/Mm hydraulic two gears, stepless | 0.5-100r/Mm hydraulic two gears, stepless |

| Longitudinal and transversal feed speed range of tool post | 1-500mm/Min | ||

| Rapid longitudinal and transversal travel speed | 3000mm/Min | ||

| Taper of quill of tailstock | Short taper flange type, taper 1:4 | ||

| Max. travel of quill of tailstock | 200mm | ||

| Main motor power | AC110/AC125kW | ||

| CNC system | SIEMENS or others, chosen by buyers | ||

Product detail pictures:

Related Product Guide:

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by providing worth added design and style, world-class producing, and repair capabilities for OEM Manufacturer Cnc Facing Lathe - Three guide ways heavy duty horizontal CNC lathe C61200S series – Premach , The product will supply to all over the world, such as: Swedish, Canberra, Lesotho, We warmly welcome domestic and overseas customers to visit our company and have business talk. Our company always insists on the principle of good quality, reasonable price, the first-class service. We have been willing to build long-term, friendly and mutually beneficial cooperation with you.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.