Wholesale Skiving And Rolling Machine - TK2620 Series CNC Six Coordinates Deep Hole Drilling Machine – Premach

Wholesale Skiving And Rolling Machine - TK2620 Series CNC Six Coordinates Deep Hole Drilling Machine – Premach Detail:

Function Description

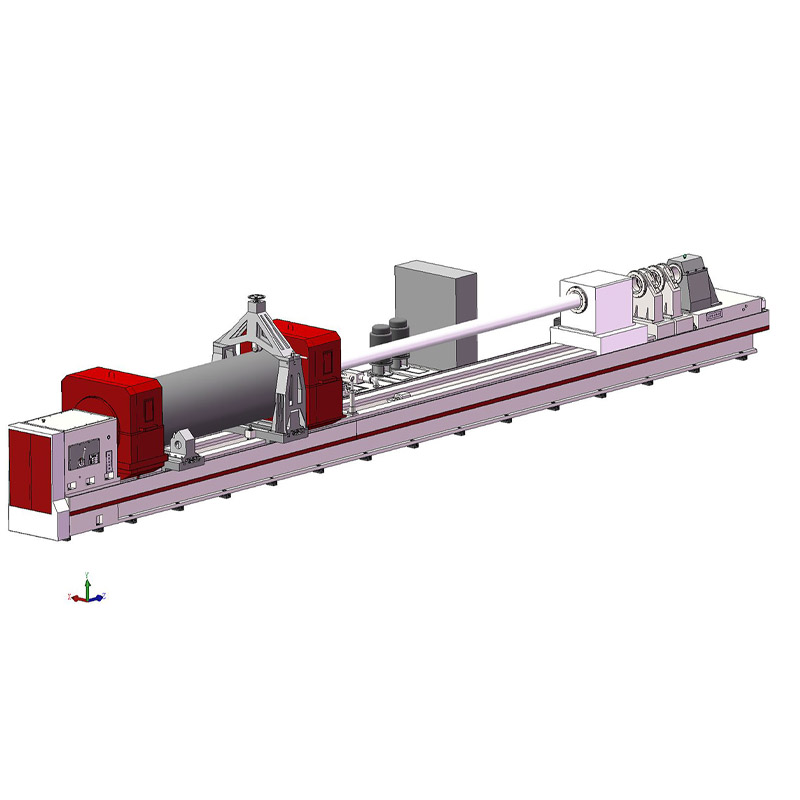

The machine tool is controlled by the CNC control system, which can control six servo coordinate axes at the same time. It can drill both row holes and coordinate holes. It can drill through the holes at one time, or turn around 180 degrees to drill holes. It has both single action performance and automatic circulation performance. Therefore, it can meet the requirements of small batch production and processing as well as the requirements of large batch production and processing.

The machine is composed of the machine body, T-slot table, CNC rotary table, W-axis servo feed system, column, travel head with gun drill and that with BTA drill, slide table, gun drill feed system and BTA feed system, guide supporter of gun drill and oil pressure head of BTA, vibration damper steady of gun drill and that of BTA, cooling system, hydraulic system, electrical control system, automatic chip removal device, and overall protection.

Technical parameter

| Drilling diameter of gun dril | Φ5-30mm |

| Max. drilling depth of gun dril | 2200mm |

| Drilling diameter of BTA | Φ25-80mm |

| Boring diameter of BTA | 40-200mm |

| Max. processing depth of BTA | 3100mm |

| Max. vertical travel of slide table (Y axis) | 1000mm |

| Max. transversal travel of work table (X axis) | 1500mm |

| Travel of CNC rotary work table (W axis) | 550mm |

| Length range of rotary workpiece | 2000-3050mm |

| Max. workpiece diameter | Φ400mm |

| Max. rotating speed of rotary work table | 5.5rpm |

| Spindle speed of travel head with gun dril | 600-4000rpm |

| Spindle speed of travel head with BTA drill | 60-1000rpm |

| Feed speed of spindle | 5-500mm/min |

| Pressure range of cutting liquid | 1-8MPa (adjustable) |

| Flow of coolant | 100, 200, 300, 400L/min |

| Max. loading weight of rotary work table | 3000kg |

| Max. loading weight of T slot work table | 6000kg |

| Rapid travel speed of travel head with rotary drill | 2000mm/min |

| Rapid travel speed of slide table | 2000mm/min |

| Rapid travel speed of T slot work table | 2000mm/min |

| Motor power of travel head with gun drill | 5.5KW |

| Motor power of travel head with BTA drill | 30KW |

| Servo motor torque of X axis | 36N.m |

| Servo motor torque of Y axis | 36N.m |

| Servo motor torque of Z1 axis | 11N.m |

| Servo motor torque of Z2 axis | 48N.m |

| Servo motor torque of W axis | 20N.m |

| Servo motor torque of B axis | 20N.m |

| Servo motor of cooling pump | 11+3X5.5KW |

| Servo motor hydraulic pump | 1.5KW |

| Size of worktable with T slot | 2500x1250mm |

| Size of rotary worktable | 800x800mm |

| CNC system | SIEMENS, FANUC or optional |

Product detail pictures:

Related Product Guide:

Bear Customer initially, High-quality first in mind, we work closely with our prospects and supply them with efficient and specialist companies for Wholesale Skiving And Rolling Machine - TK2620 Series CNC Six Coordinates Deep Hole Drilling Machine – Premach , The product will supply to all over the world, such as: Wellington, Seattle, Oman, We put the product quality and customer's benefits to the first place. Our experienced salesmen supply prompt and efficient service. Quality control group make sure the best quality. We believe quality comes from detail. If you have demand, let us work together to get success.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.