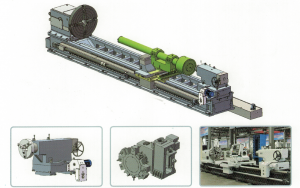

CNC horizonta lathe machine SKQ61100 series

Property of the lathe

Mated with FANUC, SIEMENS or other CNC system, with programmable control and CRT display. AC servo motor is used for longitudinal and transversal feeding, pulse encoder is used for feedback. The overall bed guide way is made of high-strength cast iron and ground after ultra- audio frequency quenching. The guide way of bed saddle is pasted with plastic, and the friction coefficient is small. If the spindle adopts frequency conversion stepless speed regulation driven or driven by servo spindle motor, the main drive of turning will be a manual four stepless speed change, which increases the constant power range. Two linkage control axes, Z axis and X axis, use ball screw pairs and AC servo motors to achieve longitudinal and transversal movement. The semi closed loop control has good positioning accuracy and repetitive positioning accuracy.

Wide cutting range, can process outer circle, inner hole and end face. Grooving, processing conical surface, chamfering, conical or cylindrical thread and arc surface.

Machine accuracy:

This machine tool implements GB / T 25659-2010 precision inspection of simple type CNC

horizontal lathe:

Finish turning outer roundness: 0.01

Machining consistency (over 300 length) 0.04

Flatness of finish turning plane (above diameter 300): 0.025 concave

Finish turning surface roughness (outer circle): 2.5 μ m

The positioning accuracy and repeat positioning accuracy of X and Z axis, please find the following table.

MAIN TECHNICAL

|

MODEL |

||||||

| ITEM | SKQ61100 | SKQ61125 | SKQ61140 | SKQ61160 | ||

| Max. swing over bed | 1000mm | 1250mm | 1400mm | 1600mm | ||

| Max. swing over cross slide | 590mm | 840mm | 1000mm | 1200mm | ||

| Distance between centers |

2000,3000,4000,5000,6000,8000,10000,12000mm |

|||||

| Bed width |

780mm |

|||||

| Spindle hole |

Φ130mm |

|||||

| Diameter of quill of tailstock |

Φ160mm |

|||||

| Max. loading weight of workpiece |

8000kg |

|||||

| Max. moving distance of tool post |

|

|||||

| longitudinal |

1500,2500,3500,4500,5500,7500, 9500,11500mm |

|||||

| transversal |

600mm |

|||||

| Spindle speed (number) | 3.15-315rpm | 2.5-250(21)r/min | 2-200r/min | |||

| 4 gears, frequency converting driven, 5-20,15-60, 25-100, 65-250 | ||||||

| Main motor power |

22KW |

|||||

| Rapid travel speed | ||||||

| longitudinal |

4m/min |

|||||

| transversal |

3m/min |

|||||

| Position number of tool post |

4, 6 or 8, optional |

|||||

| Positioning accuracy | ||||||

| longitudinal |

0.05/2000mm |

|||||

| transversal |

0.03mm |

|||||

| Repeat positioning accuracy |

|

|||||

| longitudinal |

0.025/2000mm |

|||||

| transversal |

0.012mm |

|||||

| Repeat positioning accuracy of tool pot |

0.005mm |

|||||

| Net weight |

|

|||||

| SKQ61125x3000mm |

12000kg |

|||||

| Overall dimension (LxWxH) |

|

|||||

| SKQ61125x3000mm |

6000x2700x2300mm |

|||||