CNC Horizontal Lathe

-

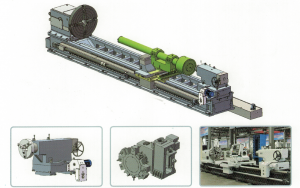

high speed large spindle bore CNC lathe CK61125

CK61125×1500 CNC lathe is a high-speed large spindle bore CNC lathe. This machine is a universal CNC horizontal lathe, which can perform all kinds of turning work. It can turn the inner and outer cylindrical surface, end face, curved surface, arc and metric thread, inch thread, modulus thread and diameter pitch thread of various parts, and can also perform grooving and cutting operations.

This machine tool has the characteristics of high power, good rigidity, high precision and good precision retention. Equipped with Japanese FANUC system, it is safe and reliable, which can ensure the reliability of the machine well. Longitudinal (Z direction), transverse (X direction) for ball screw drive, equipped with CRT display, tool compensation, graphic display, fault diagnosis and other characteristics, the main drive system for gear drive, with sliding gear to achieve 4-stage automatic hydraulic stepless transmission, the whole machine layout is compact and reasonable, pleasant, tailstock movable center with built-in rotary structure, tailstock movement with travel device, easy and fast operation. Carriage guide way is bonded with wear-resistant copper plate which greatly improves the service life of the machine and has good accuracy retention. The machine can be equipped with semi-enclosed and fully enclosed protective covers.

The main features of this machine are large spindle bore and high spindle speed. The main technical parameters of the machine tool are shown in the table below.

Project Name

Model CK61125

Maximum load of two centers 6000kg Bed width 755mm Maximum swing over bed Φ1250 Maximum turning diameter Φ880 Maximum workpiece length 1000-5000mm Headstock parameters Spindle through hole diameter Φ230mm Spindle speed series Hydraulic four-gear, stepless Spindle speed range 1-700r/min Main motor power 37kW Feed system parameter Numerical control system FANUC 0i TF Longitudinal servo motor torque 30N.m Torque of transverse servo motor 30N.m Number of tool holder stations Vertical 4-station, VDI Tool shank section 40×40 Z-axis fast forward speed 4000mm/min X-axis fast forward speed 4000mm/min Z-axis feed speed 1-2000mm/min X-axis feed speed 1-2000mm/min Tailstock parameter Quill diameter ≥Φ235mm Mandrel taper Morse 6 Quill stroke 200mm -

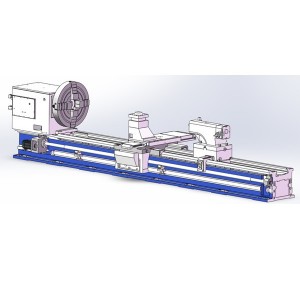

CKT61125/160/200B CNC HORIZONTAL LATHE WITH BORING BAR

This machine is a multifunctional lathe developed by our company on the basis of a large flat-bed CNC horizontal lathe with boring function. The bed is optimized, the overall weight is increased, the carriage is lengthened, widened, and thickened, and a dedicated boring tool holder is supplied. It can cut the inner holes of parts, and the processing efficiency, accuracy, and rigidity are better than ordinary CNC lathes. Adopting a semi enclosed protective structure and equipped with Siemens s... -

CKB SERIES CNC HORIZONTAL LATHE

The machines can be equipped with milling, grinding, boring units, etc. so that they can carry out the most varied machining.

-

CH61200L CNC turning center with C axis

This machine is mated with C axis, feed X and Z axis, three axis can be linkage and move together with multi-function and high cutting efficiency.

-

CNC horizonta lathe machine SKQ61100 series

MODEL SKQ61100 SWING Φ1000mm SKQ61125 SWING Φ1250mm SKQ61140 SWING Φ1400mm SKQ61160 SWING Φ1600mm Mated with FANUC, SIEMENS or other CNC system, with programmable control and CRT display. AC servo motor is used for longitudinal and transversal feeding, pulse encoder is used for feedback. The overall bed guide way is made of high-strength cast iron and ground after ultra- audio frequency quenching. The guide way of bed saddle is pasted with plastic, and the friction coefficient is small.

-

CNC lathe machine CAK series

CAK6130d series is a high-speed, high-efficiency and economical CNC lathe. It has the processing functions of turning cylindrical surface, conical surface, circular arc surface, inner hole, groove cutting and various threads. It is suitable for the single piece, small batch or batch production of various parts

-

CK series CNC lathe with slant bed

This is a CNC double coordinates, two-axis associated-action and semi-closed loop controlled turning lathe. It has the advantage of high accuracy, high efficiency and high stability. Mated with advanced CNC system, the machine has the function of interpolating linearity, oblique line, arc (cylindrical, rotary camber, spherical surface and conic section), straight and taper metric/inch screws. It is suitable for processing complicated and precision plates and shafts. The roughness after turning can reach the accuracy of grinding by other grinder.

-

CNC horizontal lathe machine SK61128 series

MODEL SK61128 SWING Φ1280mm SK61148 SWING Φ1480mm SK61168 SWING Φ1680mm SK61198 SWING Φ1980mm SK61208 SWING Φ2080mm Mated with FANUC, SIEMENS or other CNC system, with programmable control and CRT display. AC servo motor is used for longitudinal and transversal feeding, pulse encoder is used for feedback.

-

CNC horizonta lathe machine CK6186 series

MODEL CK6186 SWING Φ860mm CK61106 SWING Φ1060mm CK61126 SWING Φ1260mm Mated with FANUC, SIEMENS or other CNC system, with programmable control and CRT display, linear and circular interpolation. AC servo motor is used for vertical and horizontal feeding, pulse encoder is used for feedback, the machine adopts an integral floor bed, resin sand molding high-strength casting, high-frequency quenching, 600mm width and precision grinding of the guide way, good wear resistance and accuracy retention, large bed width and strong bearing capacity.

-

CNC horizonta lathe machine CK6163C series

MODEL CK6163C SWING Φ630mm CK6180C SWING Φ800mm CK61120C SWING Φ1200mm Mated with FANUC, SIEMENS or other CNC system, with programmable control and CRT display. AC servo motor is used for longitudinal and transversal feeding, pulse encoder is used for feedback. The overall bed guide way is made of high-strength cast iron and ground after ultra- audio frequency quenching. The guide way of bed saddle is pasted with plastic, and the friction coefficient is small.

-

CNC horizonta lathe machine CK6163B series

MODEL CK6163B SWING Φ630mm CK6180B SWING Φ800mm CK61100B SWING Φ1000mm CK61120B SWING Φ12000mm Mated with FANUC, SIEMENS or other CNC system, with programmable control and CRT display, linear and circular interpolation. AC servo motor is used for vertical and horizontal feeding, pulse encoder is used for feedback, and the width of bed guide way is 600mm. The overall bed guide way is made of high-strength cast iron and ground after ultra-audio frequency quenching.