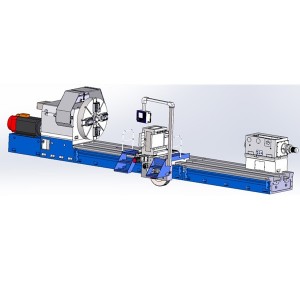

CNC pipe threading lathe, oil field & hollow spindle lathe QK1327-1363 series

Features

*Big spindle bore and double chuck allows clamp and process big diameter pipes.

*Integral machine bed adopts high strength iron casting to realize high rigidity and precision.

*Ultrasonic frequecncy quenched guide ways are hard enough for good wear-resistance.

*Equipped with taper guide bar device, this enables the machine to process taper threads.

LATHE INTRODUCTION

This series CNC pipe threading lathe is mainly used for processing the internal and external pipe threads, including metric, inch, DP and taper threads, as well as having all the common functions of normal CNC lathe such as processing the inner bore, end face of shafts and discs, this series is widely used in industries including petroleum exploiting, minerals mining, chemical piping and geological prospecting, for processing and repairing drilling pipe, drilling rod, thread coupling and son on.

Standard accessories: SIEMENS CNC contoller, electrical turret, automatic lubrication, coolant pump, semi-shield.

Optional accessies:FANUC or other CNC controller, quick change tool post, hydraulic turret or power turret, pneumatic chuck, huydraulic tailstock, pneumatic position limiter, tool setting arm, full-shield.

| specification | unit | QK1327 | QK1332 | QK1338 | |

| capacity | Swing over bed | mm | 1000 | 1000 | 1000 |

| Swing over cross slide | mm | 610 | 610 | 610 | |

| Distance between centers | mm | 1500/3000 | 1500/3000 | 1500/3000 | |

| Pipe threading range | mm | 130-270 | 190-320 | 190-380 | |

| Spindle | Guide way width | mm | 755 | 755 | 755 |

| Max. load capacity | T | 6 | 6 | 6 | |

| Spindle bore | mm | 280 | 330 | 390 | |

| Spindle speed steps | VF, 4 steps | VF, 3 steps | VF, 3 steps | ||

| Spindle speed range | rpm | 10-320 | 10-280 | 8-205 | |

| Chuck | mm | Φ800/manual 4- jaw chuck | Φ780/electrical 4- jaw chuck | Φ850/electrical 4- jaw chuck | |

| Turret | Turret/ tool post | Electrical 4 position | |||

| Tool shank size | mm | 40X40 | 40X40 | 40X40 | |

| Feed | X axis travel | mm | 520 | 520 | 520 |

| Z axis travel | mm | 1250/2750 | 1250/2750 | 1250/2750 | |

| X axis rapid travel | mm/min | 4000 | 4000 | 4000 | |

| Z axis rapid travel | mm/min | 4000 | 4000 | 4000 | |

| Tailstock | Tailstock quill diameter | mm | Φ160 | Φ160 | Φ160 |

| Tailstock quill taper | / | MT6 | MT6 | MT6 | |

| Tailstock quill travel | mm | 300 | 300 | 300 | |

| motor | Mian spindle motor | KW | 22 | 22 | 22 |

| Coolant pump motor | KW | 0.125/0.37 | 0.125/0.37 | 0.125/0.37 | |

| Dimension | Width x height | mm | 2050x2050 | 2080x2080 | 2220x2120 |

| length | mm | 4950/6450 | 5000/6500 | 5000/6500 | |

| weight | Net weight | T | 10.5/12.2 | 11.5/12.5 | 12.0/13.0 |

| Note: machine bed length can customize according to real work demand, extra long bed heavy duty lathe can customize simplified CNC pipe threading lathe without prtective cover. | |||||