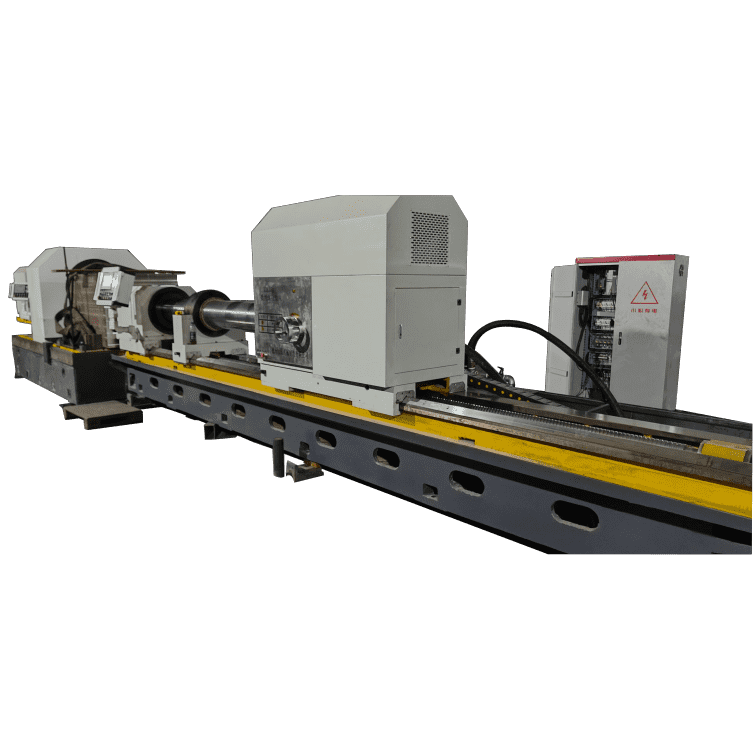

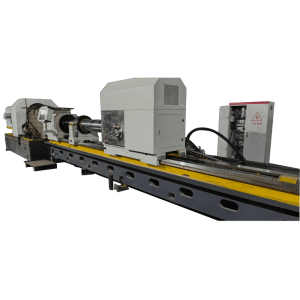

Deep-hole trepanning machine TK2150

I. Basic process performance of the machine

1) This machine can be used for trepanning the internal holes.

2) During machining, the workpiece rotates, the cutting tool feeds, and Cutting fluid enters the cutting area through the trepanning bar to cool and lubricate the cutting area and take away the metal chips.

3) When trepanning, the rear end of the trepanning bar is used for oil supply, and the end of the oil pressure head is used for cutting.

6) The machining accuracy of the machine tool:

Trepanning: Aperture accuracy IT9-10. Surface roughness: Ra6.3

Straightness of machining holes: less than 0.1/1000mm

Outlet deviation of machining hole: less than 0.5/1000mm

II. Main technical parameter

Trepanning diameter……………………………φ200-φ300mm

Max. trepanning depth………………………… 6000mm

Clamping diameter of workpiece………… φ200~φ500mm

Spindle bore ………………………………… φ130mm

Front end taper of spindle of headstock…… metric 140#

Spindle speed range………………3.15~315r/min

Feed speed……………………… 5~1000mm/min, stepless

Rapid travel speed of saddle……… 2000mm/min

Main motor………… 30kW(three-phase asynchronous motor)

Feed motor……………………………N=7.5Kw(servo motor)

Hydraulic pump motor………………… N=2.2kW,n=1440r/min

Coolant pump motor…N=7.5 kW (2 sets of embedded centrifugal pumps)

Rated pressure of coolant system………0.5MPa

Coolant flow…………………………………300,600L/min

Overall size of machine…………1700mmⅹ1600mmⅹ1800mm

III. Performance and characteristics of machine:

The TK2150 CNC trepanning machine is a specialized machine tool for processing cylindrical deep hole parts.

During trepanning process, coolant is supplied from the rear end of the trepanning bar, and the oil pressure head end is equipped with a lantern for cutting. Suitable for mass production and can also be used for single piece and small batch production.

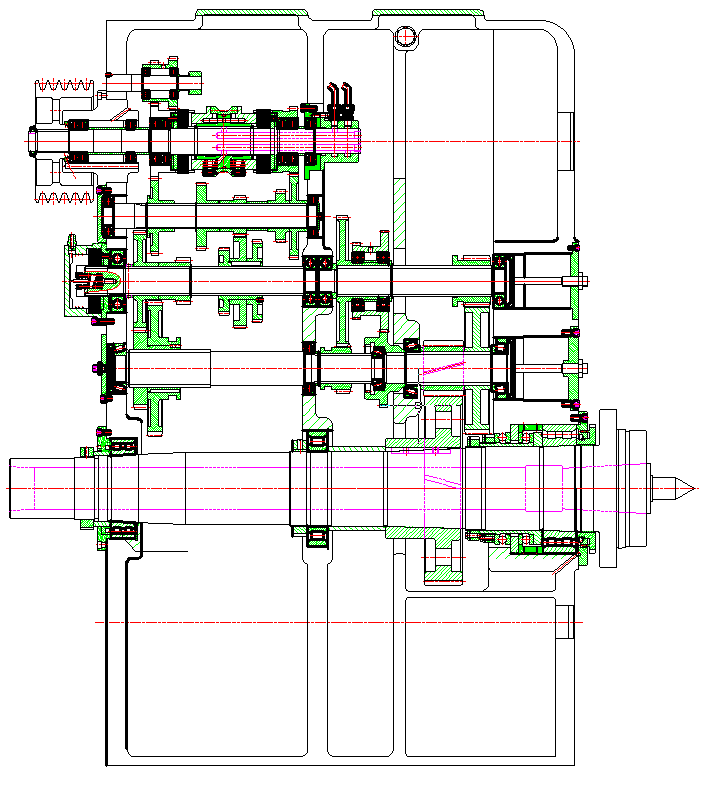

IV. main structure of the machine

1) The machine tool is composed of main components such as the bed, headstock, saddle, saddle feeding system, steady rest, vibration damper steady of trepanning bar, cooling system, electrical system, metal chip removal device, etc.

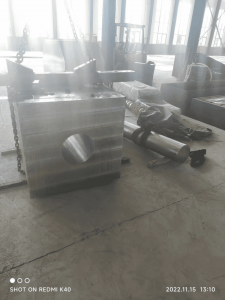

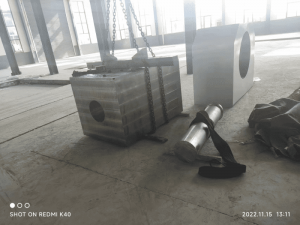

2) The bed, saddle, saddle, box, oil pressure head, supporter and other components are all made of high-strength cast iron and resin sand mould, ensuring good rigidity, strength, and accuracy retention of the machine tool. The bed adopts internationally advanced ultra-audio quenching, with a quenching depth of 3-5mm and HRC48-52, which has high wear resistance.

(1) Bed

The bed of the machine tool is composed of a combination of three pieces of bed bodies. The bed body is a structure with three closed sides and inclined rib plates, and is made of high-quality cast iron HT300 with good rigidity. The width of the bed guide rail is 800mm, which is a flat and a V-guide way with high load-bearing capacity and good guiding accuracy. The guide way has undergone quenching treatment and has high wear resistance. In the groove of the bed guide way, a feed ball screw is installed, supported by brackets at both ends and assisted by two drag frames in the middle. The drag frame can move along the guide way at the bottom of the groove, and its travel and stopping are controlled by the pull plate and rollers on the saddle. There is a T-shaped groove on the front wall of the bed, which is equipped with a fixed distance seat of vibration damper steady of boring bar, and a fixed distance seat of saddle to control the position of the vibration steady of boring bar and saddle. The front wall of the bed is equipped with racks that mesh with the gears of the manual device for moving the steady rest, supporter, and vibration damper steady of boring bar.

(2) Headstock:

Fixed at the left end of the bed, spindle bore is φ 130mm. The headstock is driven by a 30kW motor, and the spindle speed is 3.15-315r/min through multi-stage gear reduction and manual high and low gear shifting. Install a four-jaw chuck at the spindle end of the headstock to clamp the workpiece.

The headstock is equipped with an independent lubrication system to provide strong lubrication for various bearings and gear pairs

(3)Saddle and travel head

The travel head is fixed on the saddle, and during feeding, the travel head (fixed at the rear of the bed) drives the screw to rotate, causing the nut fixed with the saddle to move axially, driving the saddle to feed. When the saddle moves rapidly, the fast motor behind the saddle drives the speed reducer to rotate, driving the saddle to move quickly.

The travel head is fixed on the saddle. The main task is to clamp the trepanning bar and drive it forward and backward through the saddle.

(4)Feed box

The feed box is installed at the end of the bed and is driven by an AC servo motor. The output axis can achieve a stepless speed regulation of 0.5-100r/min. The lubrication inside the box is supplied by plunger pump driven a cam. There is a safety clutch at the connection between the output shaft and the screw, and the engagement force can be adjusted by springs. When overloaded, the clutch disengages and a microswitch is triggered to send a signal to stop the saddle (fault indicator light displayed)

(5)Steady rest and jack of workpiece

The steady rest uses three rollers equipped with rolling bearings as support for the workpiece. The lower two rollers are placed on the bracket, and the bracket moves along the guide way to support the workpiece. The front and rear brackets can be moved through the ball screw, while the upper roller is installed on the guide rod, which moves along the guide hole. After the support is completed, the guide rod needs to be fixed with screws.

The jack is equipped with two rollers with rolling bearings as the working surface. The rollers are placed on the jack, and the jack moves along the guide way to support the workpiece. The front and rear jacks can be moved simultaneously through positive and negative lead screws, and the alignment of the two rollers can be adjusted through the front adjustment sleeve. After being supported, both the jacks and guide rod need to be fixed with screws.

(6)Vibration damper steady of trepanning bar:

The vibration damper steady is used as an auxiliary support for the trepanning bar. For slender trepanning bars, it is necessary to increase the number of steady appropriately. Its movement along the bed guide way is driven by a carriage or can also be driven by a manual device. This machine tool is equipped with a set of vibration damper steady of trepanning bar.

(7)Cooling system:

The cooling system is located behind the machine tool, mainly consisting of an oil tank, a pump station, an oil pipeline, a chip storage cart, and an oil returning groove. The function of the coolant is to cool and remove metal chips.