The processing difficulty of deep hole drilling and boring machine lies in variable diameter holes, such as large belly holes, small opening diameters and large processing diameters inside. The current feasible method for processing deep hole variable diameter holes using deep hole boring machines is to use servo motor to control the radial expansion and contraction of the boring tool, thereby achieving changes in the diameter of the boring hole.

Recently, our company received an inquiry from an Indian user for about a large CNC deep hole drilling and boring machine for processing an oversized workpiece. The length of the workpiece is 17600mm, and it is a solid workpiece that needs to be drilled first and then bored. The opening diameter is only 200mm with the depth 1500mm. After the 300mm length is tapered, the inner hole diameter becomes 300mm, and the inner wall roughness after precision boring is Ra1.6, the machining size of the workpiece is symmetrical on both ends.

The user is the largest engineered to order turbo gearbox manufacturer, and the largest integrated sugar manufacturers in India.

In response to the special requirements of our customers, combined with our company's years of experience in deep hole cutting tool design and processing, we have specially designed a super large deep hole drilling and boring machine for users, with a maximum processing depth of 20000mm and a range of drilling diameters Φ 60~ Φ 160mm, boring diameter range Φ 100~ Φ 500mm, the main motor and that of drilling box adopt SIEMENS 75KW/55KW high-power servo motor.

The accuracy of the machine after processing is as follows:

Straightness of machined hole (after finishing): less than 0.1/1000mm;

Deflection of machined hole (after finishing): less than 0.5/1000mm.

The wall thickness variation of any cross section measured by ultrasonic testing shall not exceed 0.3 mm, and shall be measured at four locations along the circumference every 500 mm of length.

The outer diameter of each shaft segment shall be concentric with the central shaft, and the total indicator reading (TIR) shall be within 0.2mm. The concentricity change of any one meter of shaft length shall not exceed 0.08 mm TIR.

Electrical control system is composed of CNC system, electrical control cabinet, AC servo drive device and electrical control system.

In order to enable the machine to process variable diameter inner holes, we have designed a set of specialized variable diameter slotting devices for users. The slotting device is composed of cutting tool body, boring bar, reducer and servo motor, the radial feed mechanism in the cutting tool body is mainly used to realize the radial reaming of the ring groove in inner hole. The boring bar is composed of an outer rod and an inner rod. The outer rod is mainly used to transfer the cutting torque, and the inner rod is mainly used to transfer the power of radial feed. The servo motor provides power for radial feed.

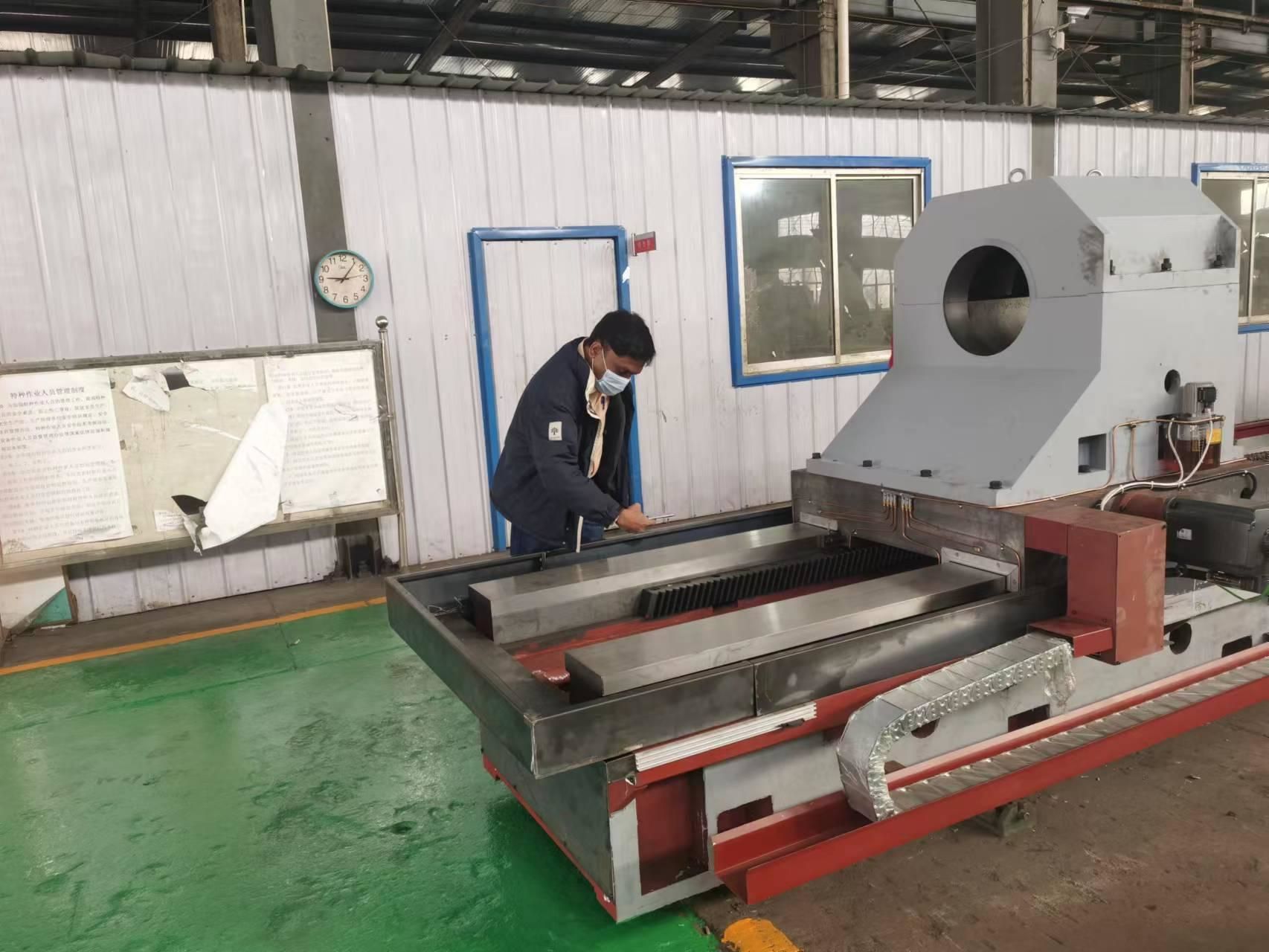

Last month, the customer came to our company for inspection and negotiation. After several video conferences and comparisons with other deep hole machine manufacturers, the customer finally ordered our company's machine tools.

The following photo shows the Indian customer conducting an inspection in our company's workshop:

Post time: May-12-2023