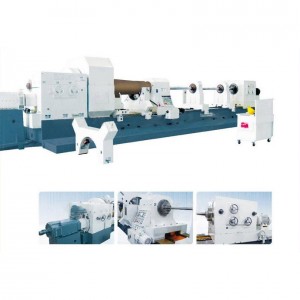

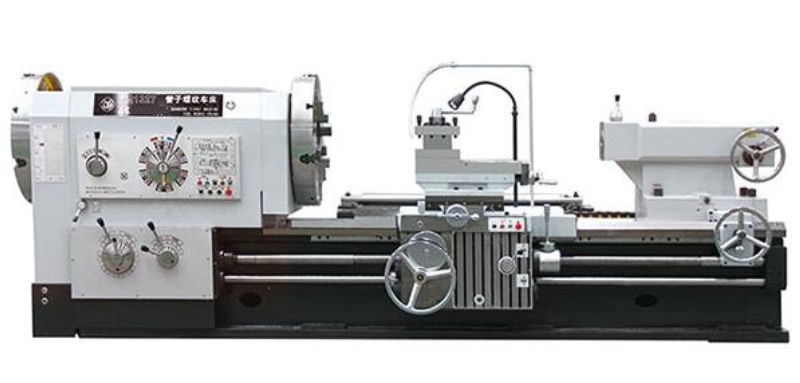

Reliable Supplier Cdk6150 Heavy Duty Big Bore Pipe Threading CNC Turning Milling Lathe

Our merchandise are broadly identified and trusted by end users and can satisfy continually developing economic and social requires for Reliable Supplier Cdk6150 Heavy Duty Big Bore Pipe Threading CNC Turning Milling Lathe, We persistently acquire our enterprise spirit “quality lives the organization, credit assures cooperation and preserve the motto within our minds: prospects first.

Our merchandise are broadly identified and trusted by end users and can satisfy continually developing economic and social requires for China CNC Machine and Pipe Threading Machine, “Good quality, Good service ” is always our tenet and credo. We take every effort to control the quality, package, labels etc and our QC will check every detail during producing and before shipment. We’re willing to establish long business relationship with individuals who seek the high quality merchandise and good service. We have set up a wide sales network across European countries, North of America, South of America, Middle East, Africa, East Asia countries.Please contact us now, you will find our professional experience and high quality grades will contribute to your business.

Features

*Big spindle bore and double chuck allows clamp and process big diameter pipes.

*Integral machine bed adopts high strength iron casting to realize high rigidity and precision.

*Ultrasonic frequecncy quenched guide ways are hard enough for good wear-resistance.

*Equipped with taper guide bar device, this enables the machine to process taper threads.

LATHE INTRODUCTION

Q13 series pipe threading lathe mainly used for turning the internal and external threads, including metric and inch thread, as well as having all the common functions of normal engine lathe such as processing the inner bore, end face of shafts and discs, equipped with taper guide bar device, it can process taper thread, this series is widely used in industries including petroleum exploiting, minerals mining, chemical piping and geological prospecting, for processing and repairing drilling pipe, drilling rod, thread coupling and son on.

| specification | unit | Q1313 | Q1319C | Q1322C | Q1325C | Q1327C | |

| capacity | Swing over bed | mm | 630/800 | 630/800 | 630/800 | 800 | 800 |

| Swing over cross slide | mm | 340/520 | 340/520 | 340/520 | 480 | 480 | |

| Distance between centers | mm | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | |

| Pipe threading range | mm | 30-126 | 50-193 | 50-220 | 50-250 | 50-270 | |

| Spindle | Guide way width | mm | 550 | 550 | 550 | 600 | 600 |

| Max. load capacity | T | 3 | 3 | 3 | 4 | 4 | |

| Spindle bore | mm | 130 | 206 | 225 | 255 | 280 | |

| Spindle speed steps | FWD,18 steps.REV. 9 steps | VF, 4 steps | |||||

| Spindle speed range | rpm | 30-650 | 20-550 | 20-420 | |||

| Chuck | mm | Φ400, manual 3-jaw chuck | Φ520/manual 4 jaw chuck | Φ630/manual 4 jaw chuck | |||

| Turret | Turret/ tool post | Manual 4 position | |||||

| Tool shank size | mm | 30×30 | 32×32 | 32×32 | 32×32 | 32×32 | |

| Feed | X axis travel | mm | 320/420 | 320/420 | 320/420 | 420 | 420 |

| Z axis travel | mm | 1350/2850 | 1350/2850 | 1350/2850 | 1250/2750 | 1250/2750 | |

| X axis feed grade/range | mm/r | 22/0.02-0.45 | 22/0.02-0.45 | 22/0.02-0.45 | 22/0.02-0.45 | 22/0.02-0.45 | |

| Z axis feed grade/range | mm/r | 26/0.07-1.33 | 26/0.07-1.33 | 26/0.07-1.33 | 26/0.07-1.33 | 26/0.07-1.33 | |

| X axis rapid travel | mm/min | 2300 | 2300 | 2300 | 2300 | 2300 | |

| Z axis rapid travel | mm/min | 4000 | 4000 | 4000 | 4000 | 4000 | |

| Metric thread grade/range | mm | 52/1-24 | 1-15 | 1-15 | 1-15 | 1-15 | |

| Inch thread grade/range | T.P.I | 40/28-2 | 14-1 | 14-1 | 14-1 | 14-1 | |

| Tailstock | Tailstock quill diameter | mm | Φ100 | Φ100 | Φ100 | Φ120 | Φ120 |

| Tailstock quill taper | / | MT5 | MT5 | MT5 | MT6 | MT6 | |

| Tailstock quill travel | mm | 250 | 250 | 250 | 250 | 250 | |

| motor | Mian spindle motor | KW | 11 | 11 | 11 | 15 | 15 |

| Rapid travel motor | KW | 0.3 | 0.3 | 0.3 | 1.1 | 1.1 | |

| Coolant pump motor | KW | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | |

| Dimension | Width x height | mm | 1500×1500 | 1500×1550 | 1650×1550 | 1700×1600 | 1700×1600 |

| length | mm | 3700/5200 | 3700/5200 | 3700/5200 | 4100/5600 | 4100/5600 | |

| weight | Net weight | T | 4.0/5.2 | 4.3/5.5 | 4.5/5.7 | 8.0/9.0 | 8.0/9.0 |

| Note: machine bed length can customize according to real work demand. | |||||||

| specification | unit | Q1327 | Q1332 | Q1338 | Q1343 | Q1350 | |

| capacity | Swing over bed | mm | 1000 | 1000 | 1000 | 1000 | 1200 |

| Swing over cross slide | mm | 610 | 610 | 610 | 610 | 710 | |

| Distance between centers | mm | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | |

| Pipe threading range | mm | 130-270 | 190-320 | 190-320 | 270-430 | 330-510 | |

| Spindle | Guide way width | mm | 755 | 755 | 755 | 755 | 765 |

| Max. load capacity | T | 6 | 6 | 6 | 6 | 6 | |

| Spindle bore | mm | 280 | 330 | 390 | 440 | 520 | |

| Spindle speed steps | FWD,12 steps. | FWD,9 steps | FWD,9 steps | FWD,9 steps | FWD,9 steps | ||

| Spindle speed range | rpm | 16-380 | 7.5-280 | 6-205 | 4.9-180 | 4.9-180 | |

| Chuck | mm | Φ800, manual 4-jaw chuck | Φ780/electrical4 jaw chuck | Φ850/electrical4 jaw chuck | Φ100/electrical4 jaw chuck | Φ1000/electrical4 jaw chuck | |

| Turret | Turret/ tool post | Manual 4position | |||||

| Tool shank size | mm | 45×45 | 45×45 | 45×45 | 45×45 | 45×45 | |

| Feed | X axis travel | mm | 520 | 520 | 520 | 520 | 520 |

| Z axis travel | mm | 1350/2850 | 1350/2850 | 1350/2850 | 1350/2850 | 1350/2850 | |

| X axis feed grade/range | mm/r | 40/0.05-1.5 | 32/0.05-0.75 | 32/0.05-0.75 | 32/0.05-0.75 | 32/0.05-0.75 | |

| Z axis feed grade/range | mm/r | 40/0.1-3 | 32/0.1-1.5 | 32/0.1-1.5 | 32/0.1-1.5 | 32/0.1-1.5 | |

| X axis rapid travel | mm/min | 1870 | 1870 | 1870 | 1870 | 1870 | |

| Z axis rapid travel | mm/min | 3740 | 3740 | 3740 | 3740 | 3740 | |

| Metric thread grade/range | mm | 30/1-30 | 23/1-15 | 23/1-15 | 23/1-15 | 23/1-15 | |

| Inch thread grade/range | T.P.I | 27/28-1 | 22/28-2 | 22/28-2 | 22/28-2 | 22/28-2 | |

| Tailstock | Tailstock quill diameter | mm | Φ160 | Φ160 | Φ160 | Φ160 | Φ160 |

| Tailstock quill taper | / | MT6 | MT6 | MT6 | MT6 | MT6 | |

| Tailstock quill travel | mm | 300 | 300 | 300 | 300 | 300 | |

| motor | Mian spindle motor | KW | 22 | 22 | 22 | 22 | 22 |

| Rapid travel motor | KW | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Coolant pump motor | KW | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | |

| Dimension | Width x height | mm | 2100×1600 | 2100×1650 | 2100×1700 | 2100×1700 | 2100×1700 |

| length | mm | 4800/6300 | 4900/6400 | 4900/6400 | 5000/6500 | 4900/6400 | |

| weight | Net weight | T | 10.0/11.5 | 11.5/13 | 12.8/14.3 | 13.0/14.5 | 15.0/16.5 |

| Note: machine bed length can customize according to real work demand. | |||||||

Our merchandise are broadly identified and trusted by end users and can satisfy continually developing economic and social requires for Reliable Supplier Cdk6150 Heavy Duty Big Bore Pipe Threading CNC Turning Milling Lathe, We persistently acquire our enterprise spirit “quality lives the organization, credit assures cooperation and preserve the motto within our minds: prospects first.

Reliable Supplier China CNC Machine and Pipe Threading Machine, “Good quality, Good service ” is always our tenet and credo. We take every effort to control the quality, package, labels etc and our QC will check every detail during producing and before shipment. We’re willing to establish long business relationship with individuals who seek the high quality merchandise and good service. We have set up a wide sales network across European countries, North of America, South of America, Middle East, Africa, East Asia countries.Please contact us now, you will find our professional experience and high quality grades will contribute to your business.