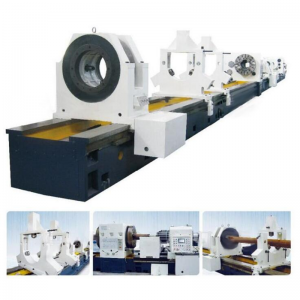

Deep Hole Pull Boring Machine TLS2210A/TLS2220B for centrifugal casting pipe

Video Display

Function Description

According to the processing requirement, the machine can also adopt the mod of the workpiece is fixed, the cutting tool rotates and feeds, and the cutting coolant enters the cutting area through the oil pressure head to cool and lubricate the cutting area and take away the metal chips.

Machining accuracy: When pull boring: hole diameter accuracy is IT8-10. Surface roughness (related to cutting tools): Ra3.2.

Machining efficiency of machine TLS2220B: Spindle speed: determined according to the cutting tool structure and workpiece material, generally is 50-500r / min.

Feed speed: determined according to the processing conditions, generally is 40-200mm / min.

The maximum machining allowance during boring: it is determined according to the cutting tool structure, material and workpiece conditions, which is generally is not greater than 14mm (diameter).

Oil pressure head is driven by servo motor and can realize self-locking. When the oil pressure head is close to the end face of the pipe, the jacking force is adjustable, and the maximum jacking force protection is provided to avoid damaging the rack. The oil pressure head can realize fast and slow movement. The oil pressure head is equipped with a control panel on which the fast and slow control button, and the tightening and loosening button of workpiece support are also on it.

The appearance of the oil pressure head is shown in the following photo:

Steady rests of workpiece: Workpiece clamping is realized by hydraulic system. The steady rest can be manually moved and their position can be adjusted according to the length of the workpiece, and the hand wheel is located on the side of the bed body. Carriage has locking mechanism.

Technical parameter

| TLS2210A | TLS2220B | ||

|

Working capacity |

Range of boring Dia. | Φ40-Φ100mm | Φ40-Φ200mm |

| Max. pull boring depth | 1-12m | 1-12m | |

| Max. clamped Dia. of workpiece | Φ127mm | Φ250mm | |

|

Spindle |

Center height from spindle center to bed | 250mm | 450mm |

| Spindle bore Dia. | Φ130mm | Φ100mm | |

| Range of spindle speed | 40-670rpm, 12 kinds | 80-500rpm, 4 gears, stepless between gears | |

|

Feed |

Feed speed range | 5-200mm/min | 5-500mm/min, stepless |

| Rapid travel speed of carriage | 2m/min | 4m/min | |

|

Motors |

Main motor power of headstock | 15KW | 30KW, frequency converting motor |

| Feed motor power | 4.5KW, A.C. servo motor | 4.5KW, A.C. servo motor | |

| Motor power of cooling pump | 5.5KW | 7.5KWx3 (one is spare) | |

|

others |

Bed width | 500mm | 600mm |

| Rated pressure of cooling system | 0.36MPa | 0.36MPa | |

| Flow of cooling system | 300L/min | 200,400L/min | |