Products

-

Deep Hole SRB Machine TGK Series

TGK CNC boring, skiving and roller burnishing machine has the smart and simple CNC operation system with high efficiency and stable performance, using environmental protection measures against oil splash and leakage.

-

engine lathe, conventional lathe C6236

This series of high-speed engine lathe can perform various turning tasks, such as turning internal and external cylindrical surfaces, conical surfaces, end faces and various threads – metric and inch threads, as well as drilling, reaming and oil drawing grooves. This machine tool can process steel, cast iron and non-ferrous metals. The dimensional accuracy of the parts processed by this lathe can reach IT6-IT7, and less roughness can be obtained. In addition to the above turning work, the saddle lathe is especially suitable for the processing of disc parts and odd shaped parts.

-

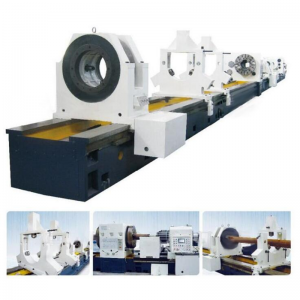

Heavy Duty Deep Hole SRB Machine TGK50/TGK63 Series

TGK50/TGK63 series heavy duty boring, skiving and roller burnishing machine adopts the processing way of the workpiece rotating and the tool feeding. It can also used the way of workpiece is fixed and cutting tools rotate and feeds. The machine can perform skiving and roller burnishing of inner hole, the machining technology is simple (once time processing is finished and formed). It has high efficiency and stable performance. The productivity is 5-10 times of the traditional deep hole boring machine. The high intelligent level and the easy operation of the digital control make the machine in a stable running.

-

horizontal engine lathe C6251-C6251V

A

Novel appearance

The appearance design of the lathe integrates the ergonomics concept into the mature machine tool structure to enhance the operating feel. The striking red and gray stamping parts are used for the main sheet metal parts, and the overall effect is beautiful.

B

Neat specifications

CA series products have complete specifications and various categories. Including straight bed lathe, saddle bed lathe and large diameter lathe.

C

Complete functions

CA series lathes can be used for turning end faces, internal and external cylinders, conical surfaces and other rotating surfaces of various materials. More accurate processing of various metric, inch, module, diametral pitch threads. In addition, drilling, reaming, pulling oil grooves and other work can also be easily competent.

D

Excellent performance

The 40A series ordinary lathe is equipped with a large diameter spindle front bearing, and has a wider bed span compared with similar products, achieving higher structural rigidity, so that the product performance reaches a new height.

standard accessories: Three jaw chuck Variable diameter sleeve and centers Oil gun Tool box and tools 1 set.

-

CNC lathe machine CAK series

CAK6130d series is a high-speed, high-efficiency and economical CNC lathe. It has the processing functions of turning cylindrical surface, conical surface, circular arc surface, inner hole, groove cutting and various threads. It is suitable for the single piece, small batch or batch production of various parts

-

slant bed CNC pipe threading lathe,oil field & hollow spindle lathe YJP-YPT series

*Big spindle bore and double chuck to ensure process big diameter pipe. *One-piece bed adopts high strength iron to ensure rigidity and precision. *Ultrasonic frequecncy quenched guide ways ensure good wear-resistance. *Carriage and guide way contact surface use Turcite B to maintain accuracy. *Double pneumatic chucks ensure hold workpiece stable and efficiency.

-

Deep hole drilling and boring machine, BTA drilling machine T2150/T2250 series

T2150 deep hole drilling and boring machine is the heavy machine tool. The workpiece is positioned by a taper plate while boring, and that is clamped by a three-jaw chuck during drilling. The oil pressure head adopts the spindle structure, which greatly improves the bearing performance and the rotation accuracy. The guide way adopts a high rigid structure suitable for deep hole machining, with large bearing capacity and good guiding accuracy; The guide way is quenched and has high wear resistance.

-

Deep hole drilling machine special for petroleum drill coller ZSK21 series

ZSK2110B CNC deep-hole drilling machine adopt BTA chip removal to drill small diameter deep-hole workpieces, is very suitable for petroleum drill collar workpiece. The biggest characteristic of this machine is that: the front end of workpiece which near to the oil pressure head is clamped by double chucks and the rear end is clamped by annular steady rest.

-

Deep Hole Drilling And Boring Machine T2163

T2163 is special equipment for machining deep cylindrical hole of workpieces. It can be perfectly suited for drilling, boring and trepanning through holes, blind and step hole in workpiece: such as, spindle of various kinds of machines, many kinds of hydraulic cylinders and cylinders. It can perform not only drilling and boring, but also rolling and trepanning. The method of the internal-removal (BTA) chip is adopted in drilling, and external metal chips removal is used for boring and trepanning.

-

ZK21 Series CNC Gun Drills Machine

This machine is a deep hole processing equipment for drilling cylindrical bar materials. It is a high-efficiency, high-precision and high-automatic machine tool for drilling small holes with external chip removal method (gun drilling method). Through one continuous drilling, the processing quality that can be guaranteed by the general drilling, expanding and reaming procedures can be achieved. The hole diameter accuracy is IT7-IT10, the surface roughness is Ra3.2-0.04μm, and the straightness of the hole center line is ≤0.05mm/100mm.

-

TK2620 Series CNC Six Coordinates Deep Hole Drilling Machine

This machine tool is a special machine tool with high efficiency, high precision and high automation. It can adopt gun drilling and BTA drilling. It can not only drill, but also boring, so as to further improve the machining accuracy and surface roughness of the workpiece.

-

Deep Hole Turning and Boring Machine TCS2150

TCS2150 is special used for machining deep hole of the cylinder, it can drill, bore and roll all kinds of holes of hydraulic cylinders and spindles of the machine.

Metal chips removing method adopt BTA method while drilling, it means that the metal chips will be removed to the receiver in the end of the machine through inside of the drilling rod. And the metal chips removing method adopt forward removing method while boring, boring method is push boring.