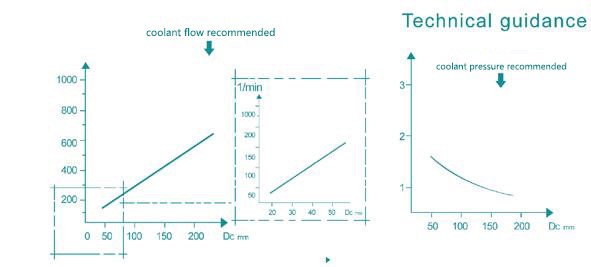

Technical guidance

Technical guidance

The cutting parameters are for reference only and adjusted according to the actual processing conditions. Compared with the mixed lotion, the pure oil can improve the service life of the tool.

Problems and resolution

|

S.N. |

problem |

reason |

Resolution |

|

1 |

Broken metal chips are too small |

Wrong cutting parameter |

Adjust cutting speed and feed |

|

The broken chip is groove-type wrong, and the elliptical angle is too small or too deep |

Change the groove type of broken chip |

||

|

Workpiece material is unstable |

Adjust the appropriate speed and feed |

||

|

Poor initial cutting (workpiece is no centering) |

Centering the workpiece |

||

|

2 |

Broken metal chips are too small |

Wrong cutting parameter |

Adjust cutting speed and feed |

|

The broken chip is groove-type wrong, and the elliptical angle is too small or too shallow |

Change the groove type of broken chip |

||

|

3 |

Broken metal chips are not stable |

Workpiece material is not stable |

Adjust cutting speed and feed, change the groove type of chips |

|

Wrong feed mod (e.g., hydraulic feed mod) |

Consult the machine maker or sales engineer |

||

|

insufficient cooling leads to clogging of chip discharge |

Increase coolant |

||

|

Strong vibration caused by insufficient rigidity of workpiece and tool |

Consult the machine maker or sales engineer |

||

|

4 |

Fibrous metal chips |

Workpiece material is not stable |

Adjust cutting speed and feed, change the groove type of chips |

|

Wrong feed mod (e.g., hydraulic feed mod) |

Consult the machine maker or sales engineer |

||

|

Coolant is contaminated |

Clear coolant |

||

|

Chemical affinity reaction between workpiece and cemented carbide tool |

Check and replace the tool brand |

||

|

Cutting edge chipping |

Replace insert or drilling head |

||

|

Feed speed is too low |

Increase feed speed |

||

|

5 |

Cemented carbide broken edge |

Cutting tool is too blunt |

Replace insert or drilling head |

|

Insufficient coolant |

Check the coolant flow and pressure |

||

|

Coolant is contaminated |

Clear coolant |

||

|

The tolerance of guide sleeve is too small |

Replace the guide sleeve if need |

||

|

Eccentric between drilling rod and spindle |

Correct the eccentric |

||

|

Wrong parameter of insert |

Change the parameter of insert |

||

|

Workpiece material is unstable |

Adjust the appropriate speed and feed |

||

|

6 |

Tool life is shortened |

Feed or rotating speed is not appreciated |

Adjust the feed and rotating speed |

|

Unsuitable hard alloy grade or coating |

Choose suitable alloy grade as per workpiece material |

||

|

Insufficient coolant |

Check the coolant temperature and cooling system |

||

|

Wrong coolant |

Replace coolant if need |

||

|

Eccentric between drilling rod and spindle |

Correct the eccentric |

||

|

Wrong parameter of insert |

Change the parameter of insert |

||

|

Workpiece material is unstable |

Adjust the appropriate speed and feed |

||

|

7 |

Poor surface roughness |

eccentric |

Check and adjust |

|

The chip breaking groove is too large or lower than the center line |

Choose the correct chip breaking groove |

||

|

Wrong size of tool or guide pad |

Choose the correct tool |

||

|

Eccentric between workpiece and drilling head |

Correct the eccentric |

||

|

Strong vibration |

Consult the machine maker or adjust cutting parameter |

||

|

Wrong parameter of insert |

Change the parameter of insert |

||

|

Cutting speed is too low |

Increase cutting speed |

||

|

Feed speed is too low during machining hard material workpiece |

Increase feed speed |

||

|

Feed is not stable |

Improve the feed structure |

||

|

8 |

Eccentric |

The deviation of the workpiece from the machining center of the machine is too large |

Adjust again |

|

Drilling rod is too long, linearity is poor |

Adjust again |

||

|

Wear of insert and guide pad |

Replace insert or other parts |

||

|

Reason for workpiece material (characteristic, hardness and impurity etc.) |

Choose suitable tool and cutting parameter |

||

|

9 |

Screw hole |

Outer insert edge is broken |

Replace insert |

|

The guide pad is worn or the support is insufficient |

Replace or adjust |

||

|

Excessive centering eccentricity of machine and workpiece |

Adjust again |

||

|

Coolant and lubrication is not sufficient |

Adjust coolant and coolant structure |

||

|

Cutting edge is too blunt |

Replace insert |

||

|

Wrong cutting parameter |

Adjust parameter |

||

|

Rigidity and feed power is not enough |

Adjust machine or reduce drilling diameter |

||

|

10 |

Vibration is too large during processing |

Cutting edge is too blunt |

Replace insert |

|

Wrong cutting parameter |

Adjust parameter |

||

|

Rigidity of machine or feed power is insufficient |

Adjust machine or reduce drilling diameter |