Products

-

bench lathe CZ1237G-1 CZ1337G-1

*4-handles gearbox

*V-way bedways induction hardened and ground;

*Cross and longitudinal interlocking feed, enough safety;

*ASA D4 cam-lock spindle nose;

*Various threads cutting functions available -

double column vertical lathe C52 series

This machine is a double column vertical lathe, which is an advanced equipment with excellent performance, wide range of technology and high production efficiency.

-

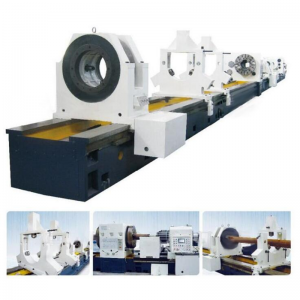

Deep Hole Drilling And Boring Machine T2150/T2250 Series

T2150 deep hole drilling and boring machine is the heavy machine tool. The workpiece is positioned by a taper plate while boring, and that is clamped by a three-jaw chuck during drilling. The oil pressure head adopts the spindle structure, which greatly improves the bearing performance and the rotation accuracy. The guide way adopts a high rigid structure suitable for deep hole machining, with large bearing capacity and good guiding accuracy; The guide way is quenched and has high wear resistance. The machine tool has the functions of drilling, boring, rolling and trepanning. Suitable for machining the center hole of shaft parts. PLC control system and touch screen are adopted for simple operation; The above ground oil tank is adopted for the cooling system.

-

CNC pipe threading lathe, oil field & hollow spindle lathe Q1313-1319-1322 series

This machine tool is designed and manufactured for thread processing of oil pipe, drill pipe and casing in petroleum, chemical and metallurgical industries. It can turn all kinds of internal and external threads (metric, inch and taper pipe threads) accurately through the automatic control of CNC system. It is especially suitable for thread processing with mass production. This machine can also process rotary parts. For example, rough and finish machining of internal and external cylindrical surfaces, conical surfaces, circular surfaces, and medium and small batches of shaft and disk parts. It has the characteristics of high automation, simple programming and high machining accuracy.

The machine tool has two linkage control axes, semi closed loop control. The Z-axis and X-axis use ball screw pairs and AC servo motors to achieve vertical and horizontal movement, with good positioning accuracy and repeated positioning accuracy.

-

Hones, Deep Hole Honing Machine Jhc Series With Steel Plate Welded Bed

This deep hole powerful honing machine is equipped with PLC controller or CNC system (optional), linear rolling guide way, AC servo motor, grinding rod adopts stepless speed regulation, stable commutation, convenient speed regulation, easy to ensure the accuracy of hole size, and reduce labor intensity. In the honing process, the sand rod and the workpiece always maintain constant pressure, so that the sand rod can be strongly ground. It ensures the high efficiency of deep hole machining, and is suitable for rough and fine honing of general cylindrical deep hole parts. This type of machine tool can also be used for partial honing to correct the taper and ellipticity of parts and the partial hole error.

-

CNC pipe threading lathe,oil field & hollow spindle lathe QK1325-1327C series

*Big spindle bore and double chuck to ensure process big diameter pipe. *One-piece bed adopts high strength iron to ensure rigidity and precision. *Ultrasonic frequecncy quenched guide ways ensure good wear-resistance. *Carriage and guide way contact surface use Turcite B to maintain accuracy.

-

CNC pipe threading lathe, oil field & hollow spindle lathe QK1327-1363 series

QK1327 and QK1363 series machine tools are horizontal flat bed CNC hollow spindle lathes with semi closed loop control. Two linkage control axes, Z-axis and X-axis use ball screw pairs and AC servo motors to achieve longitudinal and lateral movement, with good positioning accuracy and repeated positioning accuracy.

This machine tool is designed and manufactured for thread processing of all kinds of pipes in petroleum, chemical and metallurgical industries. It can turn all kinds of internal and external threads (metric, inch and taper pipe threads) accurately through the automatic control of CNC system. This machine tool can also process rotary parts as a normal conventional lathe. For example, rough and finish machining of internal and external cylindrical surfaces, conical surfaces, circular surfaces, and medium and small batches of shaft and disk parts. It has the characteristics of high automation, simple programming and high machining accuracy.

-

Deep hole drilling and boring machine, BTA drilling machine T2150/T2250 series

T2150 deep hole drilling and boring machine is the heavy machine tool. The workpiece is positioned by a taper plate while boring, and that is clamped by a three-jaw chuck during drilling. The oil pressure head adopts the spindle structure, which greatly improves the bearing performance and the rotation accuracy. The guide way adopts a high rigid structure suitable for deep hole machining, with large bearing capacity and good guiding accuracy; The guide way is quenched and has high wear resistance.

-

Deep hole drilling machine special for petroleum drill coller ZSK21 series

ZSK2110B CNC deep-hole drilling machine adopt BTA chip removal to drill small diameter deep-hole workpieces, is very suitable for petroleum drill collar workpiece. The biggest characteristic of this machine is that: the front end of workpiece which near to the oil pressure head is clamped by double chucks and the rear end is clamped by annular steady rest.

-

Deep Hole Drilling And Boring Machine T2163

T2163 is special equipment for machining deep cylindrical hole of workpieces. It can be perfectly suited for drilling, boring and trepanning through holes, blind and step hole in workpiece: such as, spindle of various kinds of machines, many kinds of hydraulic cylinders and cylinders. It can perform not only drilling and boring, but also rolling and trepanning. The method of the internal-removal (BTA) chip is adopted in drilling, and external metal chips removal is used for boring and trepanning.

-

ZK21 Series CNC Gun Drills Machine

This machine is a deep hole processing equipment for drilling cylindrical bar materials. It is a high-efficiency, high-precision and high-automatic machine tool for drilling small holes with external chip removal method (gun drilling method). Through one continuous drilling, the processing quality that can be guaranteed by the general drilling, expanding and reaming procedures can be achieved. The hole diameter accuracy is IT7-IT10, the surface roughness is Ra3.2-0.04μm, and the straightness of the hole center line is ≤0.05mm/100mm.

-

TK2620 Series CNC Six Coordinates Deep Hole Drilling Machine

This machine tool is a special machine tool with high efficiency, high precision and high automation. It can adopt gun drilling and BTA drilling. It can not only drill, but also boring, so as to further improve the machining accuracy and surface roughness of the workpiece.